Key Features

Key features of ERP software for syrups manufacturing streamline the entire production process—from ingredient sourcing to finished product distribution—ensuring quality, compliance, and operational efficiency.

Syrup Formulation

Taste Control

Heat Treatment

Density Control

Blend Consistency

Cycle Tracking

Yield Analysis

Recipe Adjustments

Sweetener Tracking

Ingredient Assurance

Bulk Management

Packaging Control

Shelf Life

Temperature Monitoring

Supplier Audits

Storage Management

Brix Monitoring

Labeling Compliance

Ingredient Traceability

Certification Management

ISO Documentation

Allergen Detection

Safety Audits

Environmental Reporting

Out of the box Features

Empower your syrup manufacturing with ERP—optimizing formulation, ensuring quality, and delivering efficiency through data-driven insights.

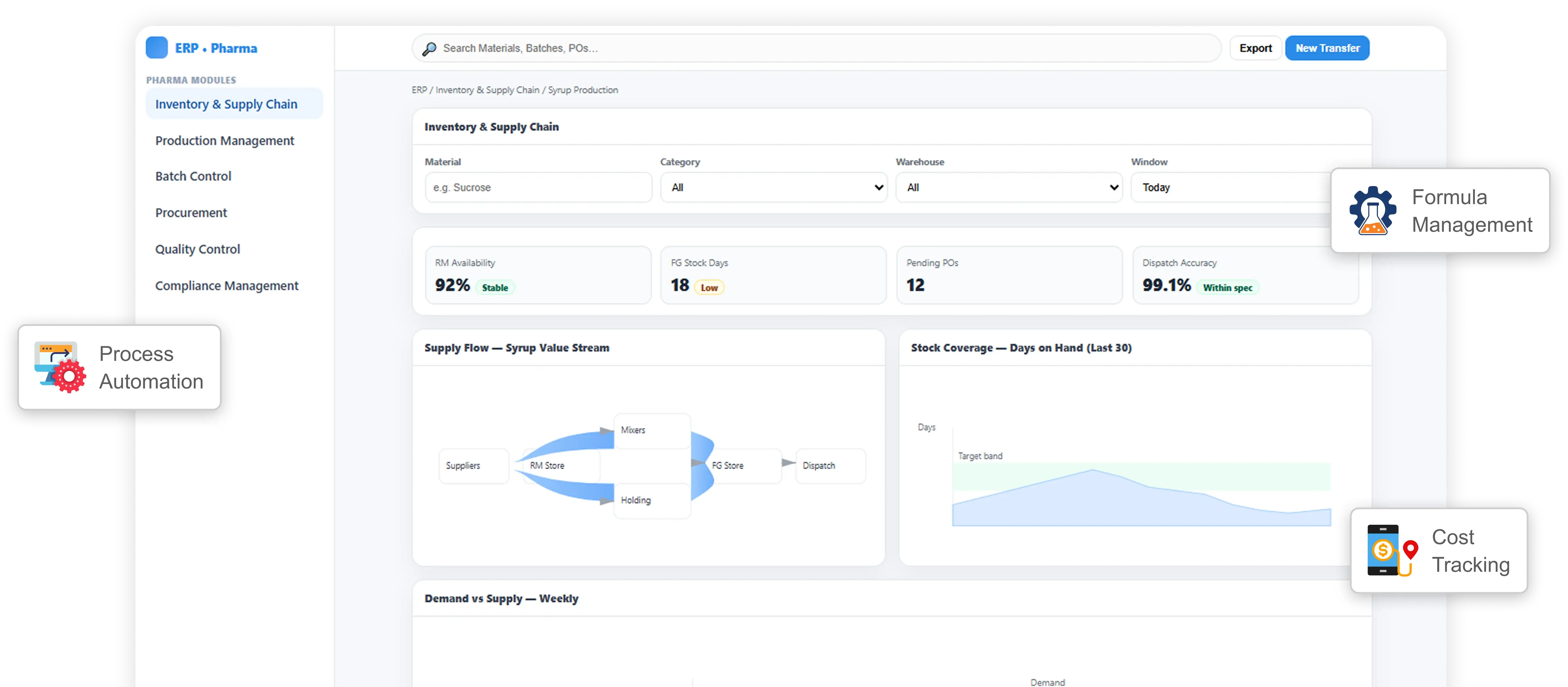

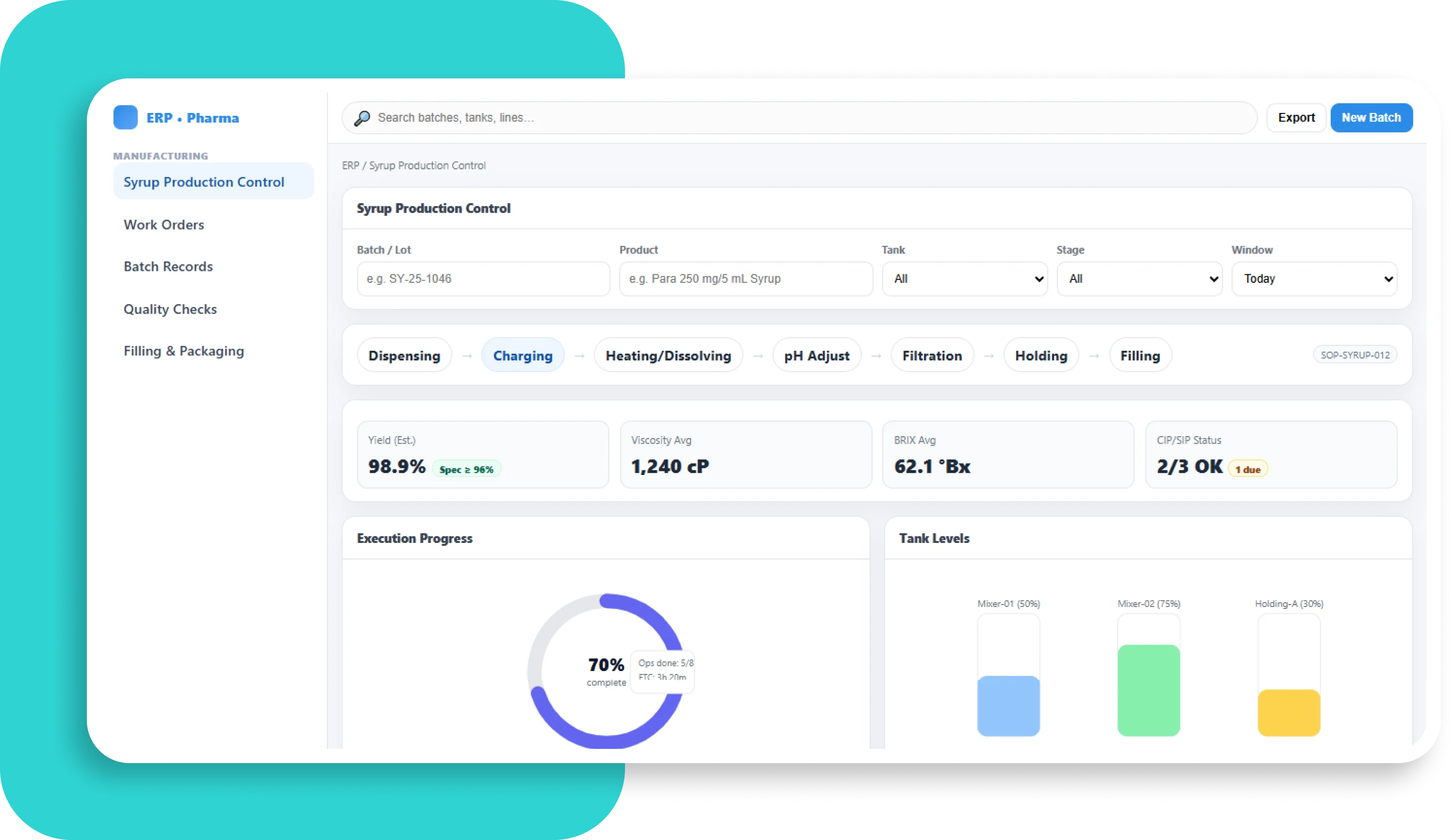

Syrup Production

Control

Manage and monitor syrup production processes in real-time. Optimize syrup concentration, viscosity, and texture to achieve the perfect balance for each batch.

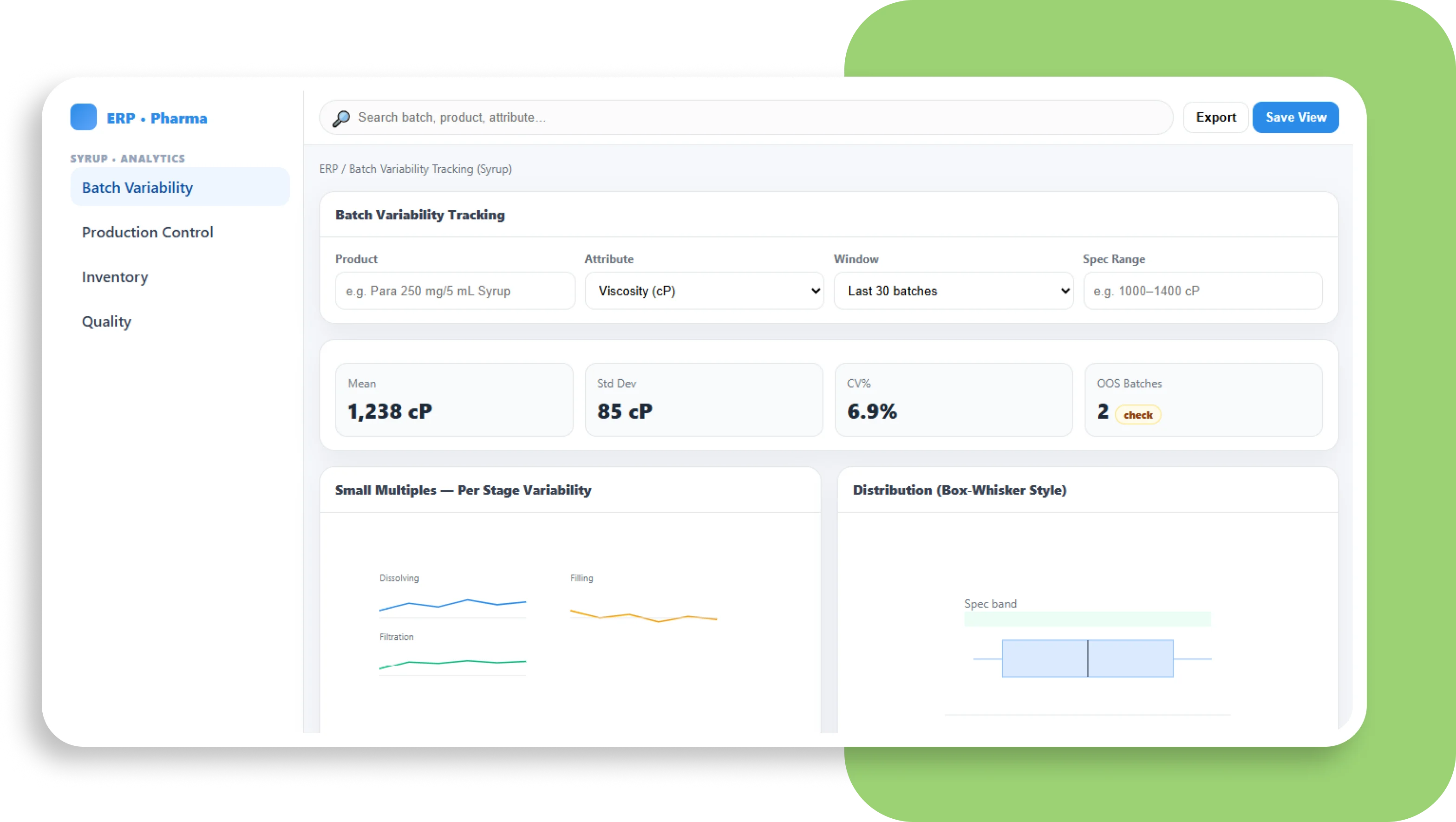

Batch Variability &

Tracking

Track and manage batch-to-batch variability, ensuring that each production run aligns with the desired taste profile, sweetness level, and consistency.

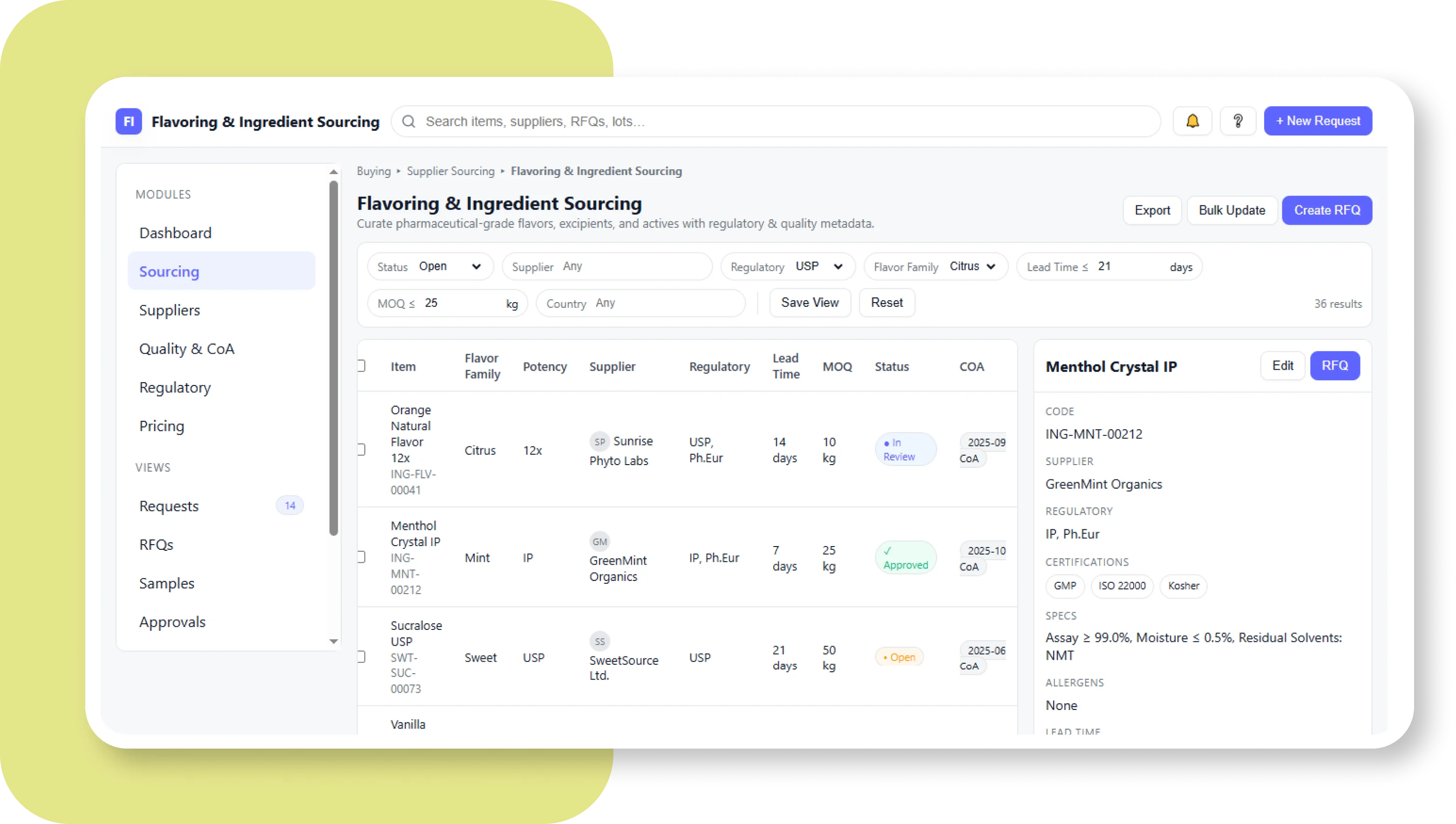

Flavoring & Ingredient

Sourcing

Track the procurement and use of diverse flavoring agents, sweeteners, and natural extracts. Ensure quality and consistency in the selection of raw materials for each production batch.

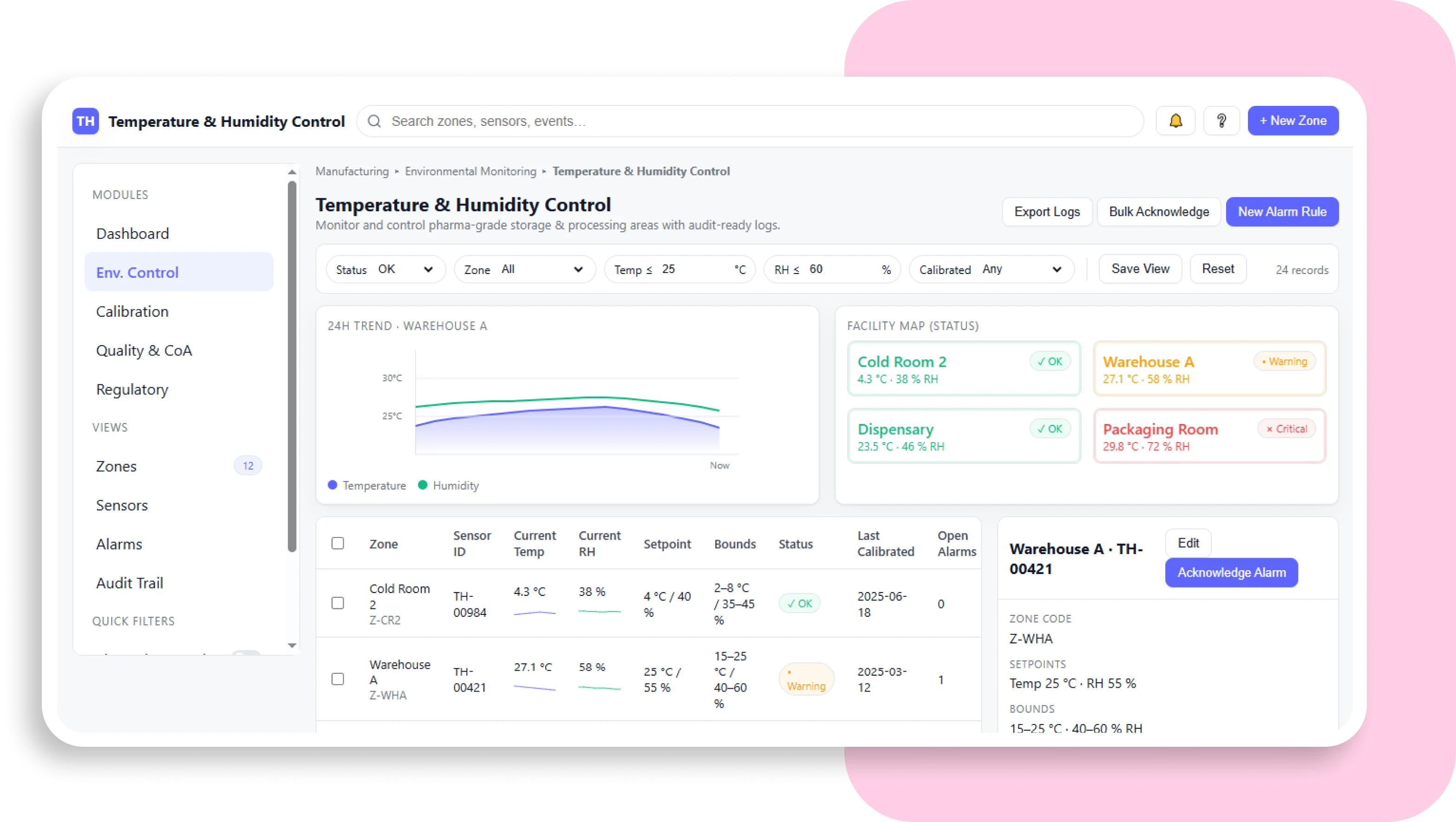

Temperature & Humidity

Control

Monitor and control production environments, such as temperature and humidity, critical to syrup consistency, shelf-life, and quality during production and storage.

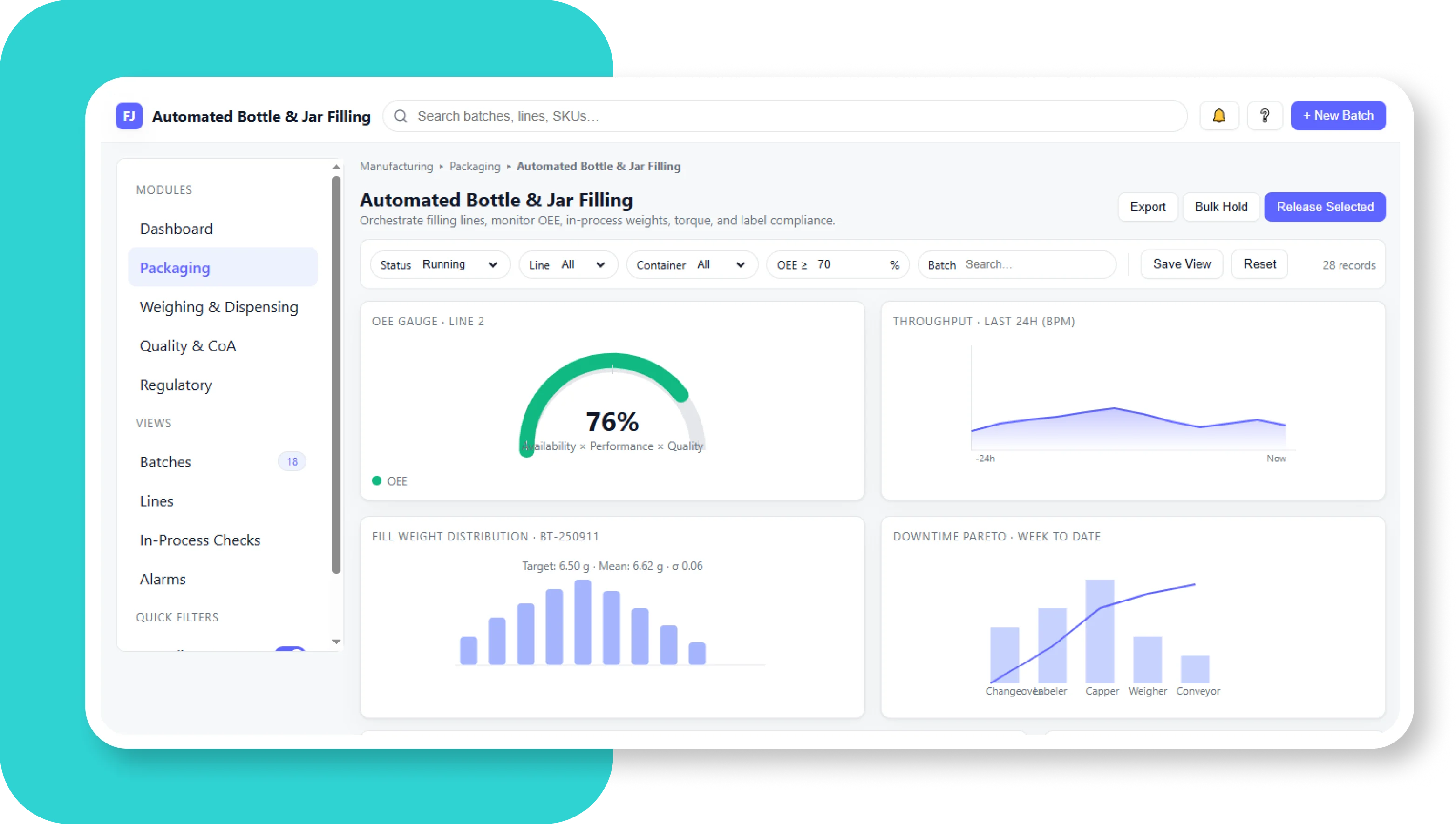

Automated Bottle &

Jar Filling

Integrate automated systems for accurate syrup filling in bottles, jars, or other containers. Minimize human error, improve production speed, and ensure consistent packaging.

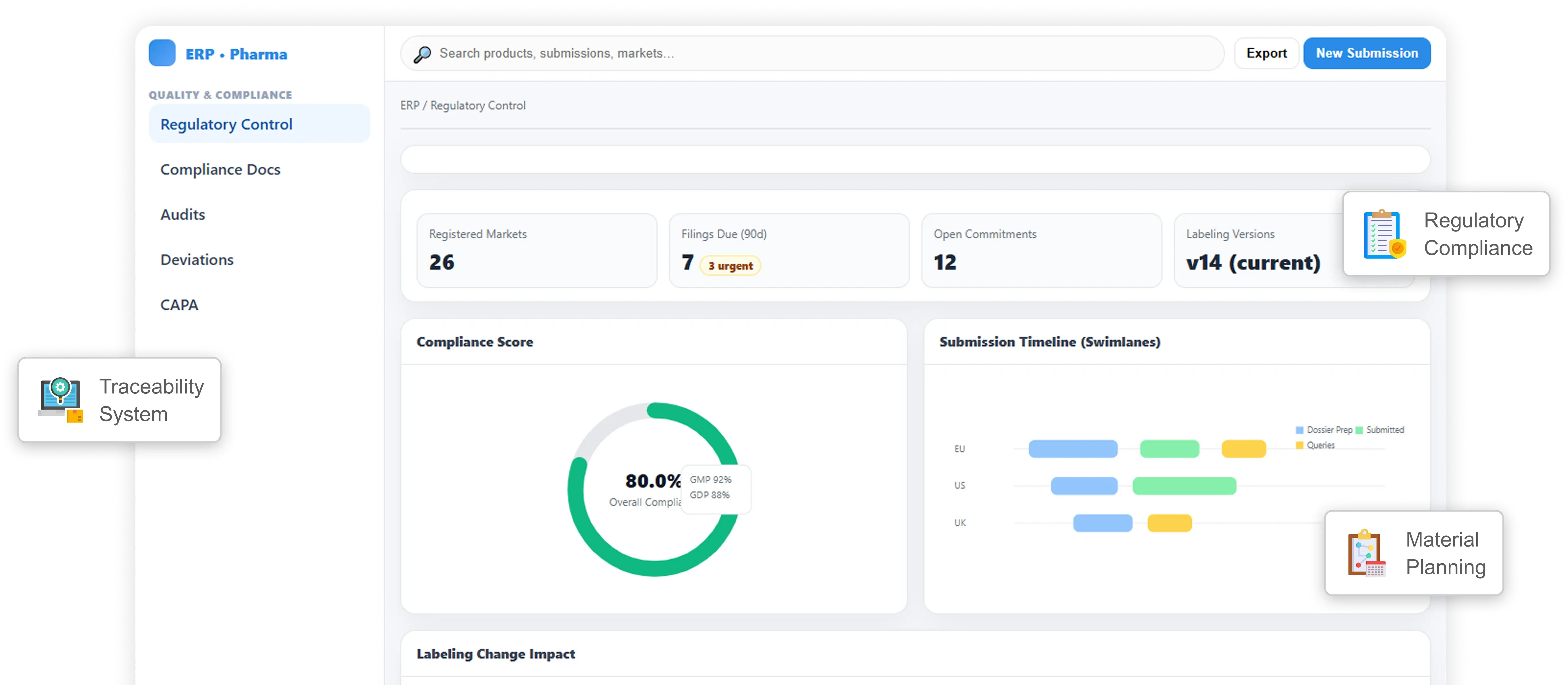

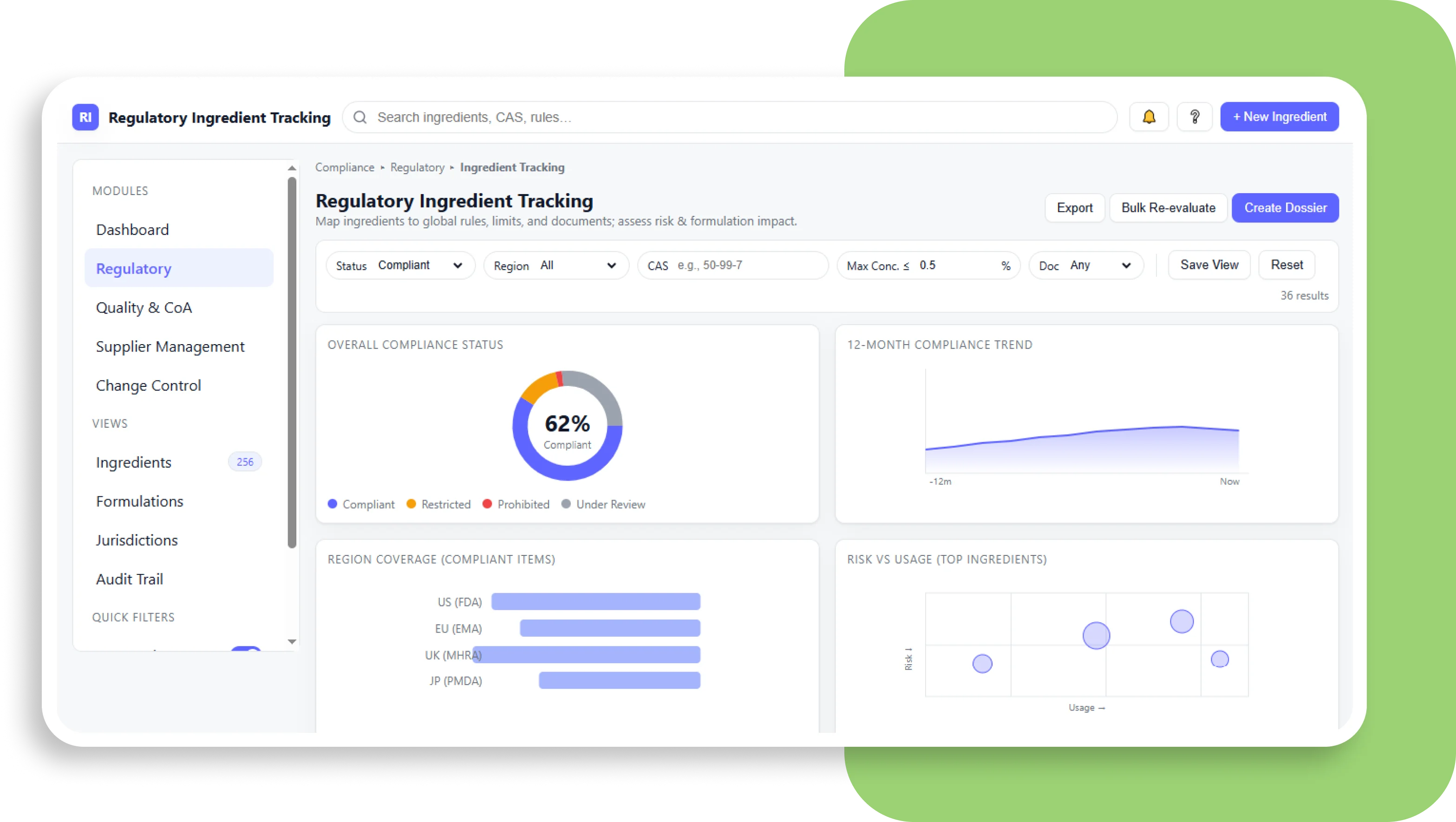

Regulatory Ingredient

Tracking

Ensure full traceability of every ingredient used in syrup production, from sourcing to final product. Maintain records of all regulatory and quality certifications, ensuring full compliance with food safety regulations.

Why Choose NestorBird

NestorBird is one of the leading ERP solution providers in North India. We deliver world-class pharmaceutical

ERP software designed for tablets, injections, syrups, and chemical manufacturing companies worldwide.

Tablet Producers

Injection Facilities

Syrup Factories

Chemical Labs

Capsule Producers

Pharma Plants

API Labs

Herbal Units

Drug Suppliers

Looking for the Best ERP Software for

Syrup Manufacturing?

Optimize your syrup production process with NestorBird ERP solutions. Automate workflows, improve inventory management, ensure quality control, and meet regulatory standards—all in one integrated system.

Industries Powered by ERPNext

Frequently Asked Questions

ERP software automates the syrup production process, from raw material procurement to packaging, ensuring consistency, quality control, and increased production efficiency.

Yes, ERP software helps monitor ingredient quality and recipe formulations, ensuring that each batch of syrup maintains the same flavor profile and consistency.

ERP systems provide real-time tracking of raw materials such as sweeteners and flavorings, helping manufacturers manage stock levels, minimize waste, and avoid production delays.

Yes, ERP systems integrate packaging and labeling management, ensuring that each product complies with industry standards and regulations for labeling, including nutritional facts and allergen warnings.

Yes, ERP software tracks the shelf life of syrup batches, manages expiry dates, and supports stock rotation to prevent expired products from being distributed.

ERP software ensures complete batch traceability by tracking every ingredient used in production, allowing manufacturers to monitor each batch’s journey from procurement to final distribution.

Yes, ERP systems are designed to manage multiple production sites. They provide centralized control, ensuring consistent processes and data across different locations.

ERP systems generate automated compliance reports, track certifications, and maintain audit trails to ensure that syrup production meets regulatory standards like FDA and GMP.

Yes, ERP systems can track and manage temperature and humidity conditions during syrup production, which are crucial for maintaining product quality and consistency.

ERP software allows manufacturers to track supplier performance, monitor ingredient quality, and manage supplier contracts to ensure timely and cost-effective procurement of raw materials.

Transform Your Syrup Manufacturing with ERPNext

An advanced ERP solution that streamlines Syrup Manufacturing operations, empowers efficiency in mission delivery & impact management.

Drop Your Query NowA 100% Guaranteed Solution for Healthcare Organizations