Quick Summary

Choosing the right ERP software for transformer industry helps you manage production, inventory, and quality in one place. It reduces mistakes, saves time, and makes your transformer business run smoothly and efficiently.

Table Of Contents

Introduction

If you are running a transformer business, you may be dealing with handling and maintaining various important operations and business functions all at once, for proper smooth business daily. Keeping track of orders, inventory, production, and quality can get confusing and stressful. Mistakes can easily happen if information is spread across different places or managed by hand. ERP software for transformer industry can help, and with the right system, you can manage all your business tasks in one place, reduce errors, and make your daily work much easier. In this blog post, we will explain how ERP for transmission industry can solve these problems and help your transformer business run better.

Key Takeaways

ERP software for transformer industry helps manage all business tasks in one place.

It improves production planning and reduces mistakes in daily work.

Real-time inventory tracking prevents shortages and overstocking.

Automated quality checks help meet industry standards easily.

Financial reports and records are more accurate and simple to access.

Some of the Operational Challenges in Transformer Manufacturing

Handling daily operations in transformer manufacturing is not easy. Many businesses face problems that slow down work and make customers unhappy. Let’s look at some common challenges and how they affect growth and customer satisfaction.

Manual processes and data silos: When information is kept in different places or managed by hand, it is easy to lose track of important details, which mainly causes mistakes, double work, and confusion between teams. It also slows down the whole business and can lead to unhappy customers.

Inventory tracking and procurement delays: Without a good system, it is hard to know what materials you have or need, and this can lead to running out of stock or ordering too much. That’s why delays in getting parts can stop production and make customers wait longer for their orders.

Production scheduling complexity: Proper planning of production is tough when there are many steps and custom orders, and if your schedules are not clear, machines and workers may sit idle or get overloaded. This leads to missed deadlines and wasted resources for your business.

See How ERP Enhances Efficiency Compliance Pharma.

Quality control and compliance: Making sure every transformer meets quality and safety rules is very important, and the manual checks can miss problems or fail to keep up with changing regulations. So here, poor quality or missed standards can damage your reputation and lead to costly fixes.

High financial accuracy and reporting: Tracking costs, sales, and profits is hard when data is scattered, and moreover, many mistakes in financial reports can lead to wrong decisions and trouble with audits. So good records are needed to plan for growth and keep the business healthy.

These challenges make it hard for transformer manufacturers to grow, keep customers happy, and stay ahead in a tough market. Using the right tools can help solve these problems and support business success.

Know the biggest Retail ERP Trends.

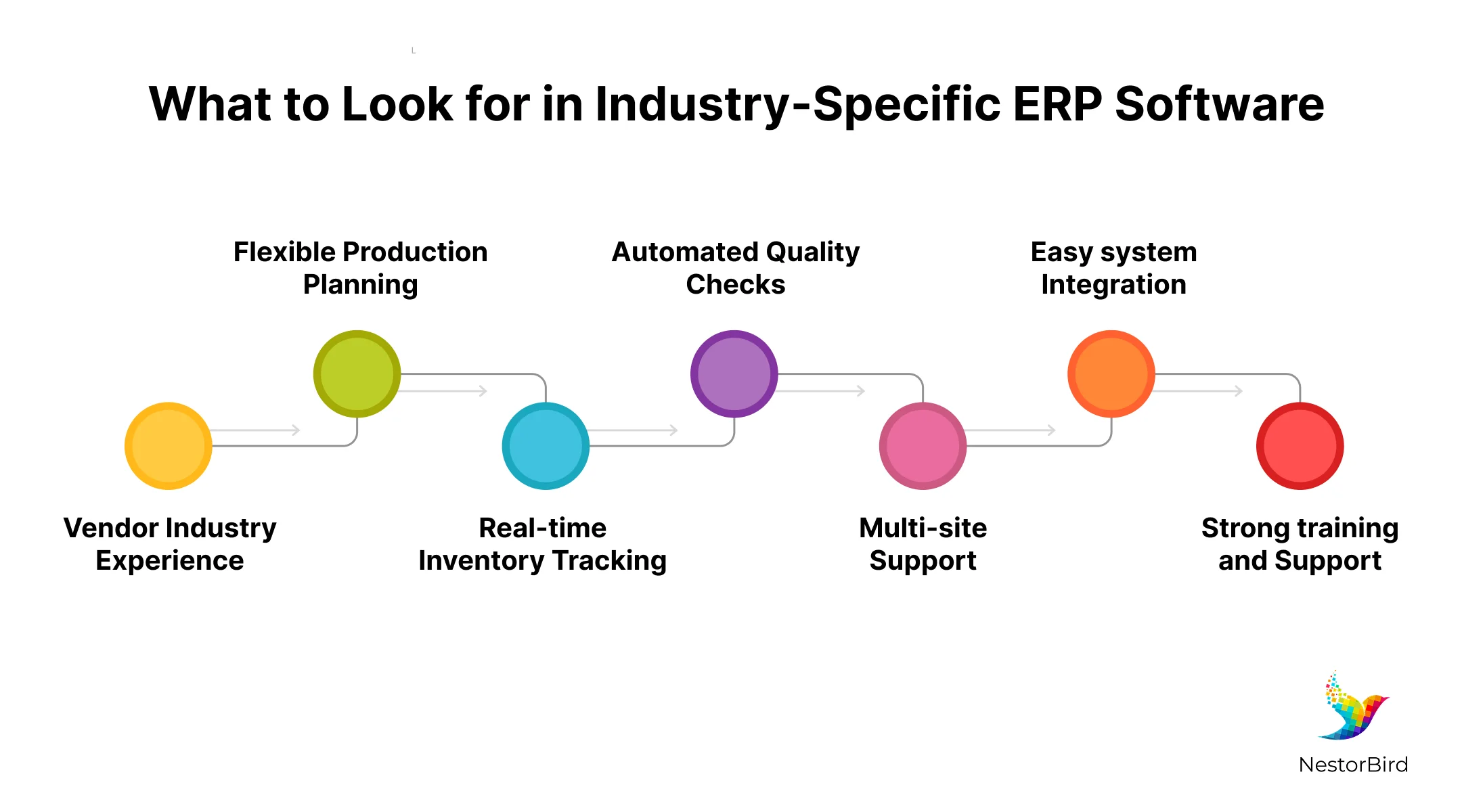

What to Look for in Industry-Specific ERP Software?

Industry-specific ERP software is designed for the unique needs of the transformer industry, while generic ERP systems are made for all types of businesses. Industry-specific ERP helps you manage your exact processes, follow rules, and solve your daily problems more easily. This makes your work smoother and more efficient.

Flexible production planning to help with growth and business success

This feature lets you adjust your production schedules based on orders, machine availability, and material stock. You can quickly make changes if something urgent comes up or if you get a new order, which helps you avoid delays and keep your customers happy.

Real-time inventory management for efficient operations

With real-time inventory, you always know what materials and products you have, and then the system updates stock levels automatically as you use or receive items, to help you avoid running out of important parts and reduce wastage of any kind.

Here are the Top Retail ERP Software Features.

Efficient automated quality checks and compliance tracking

The software can check product quality and make sure you follow safety rules without manual work, and records every check and alert, so you can fix problems quickly and always meet industry standards.

Multi-site and multi-currency support for your transformer business

If you have more than one factory or work with customers in different countries, this feature helps you manage all locations and currencies in one system, to make business easier and helps you grow without confusion.

Integration with existing systems and setup

A good ERP for Transmission Industry should work well with your current tools, like accounting or transformer software, which actually means you do not have to enter the same data twice, and all your information stays up to date everywhere.

Top Benefits of Implementing ERP Systems And Software for Transmission Industry

Here’s a list of the bar software selection options, that have different useful and beneficial features of bar management in a simple and effective way for your business.

Automation in ERP software for transformer industry helps you finish tasks faster and with fewer mistakes.

You can see all your business data in one place, so you have better control over every part of your operations.

Inventory and purchasing are always up to date, so you never run out of important parts or order too much.

Your yearly or regular financial records and reports are more accurate, making it easier to track profits and plan for the future.

Compliance and quality checks are built in, so you always meet industry rules and deliver good products.

Check out the Cloud-Based ERP for Retail.

Choosing the Best ERP Software for Transformer Industry

When choosing the best ERP software for transformer industry, start by checking if the vendor has experience with transformer businesses. This means they understand your needs and challenges. The software should be flexible and scalable, so it can grow with your company and handle changes easily, also good support and training are important, as your team will need help to use the system well.

Some of the leading solutions to consider include Lighthouse ERP, which is made for transformer manufacturing, and ERPNext Manufacturing, known for its easy automation and all-in-one features. These options offer strong tools for managing production, inventory, and compliance, making them top choices for the transformer sector.

Conclusion

Always choose the right ERP software for transformer industry, which is important to improve your business operations. It helps you manage production, inventory, quality, and finances all in one place. Using the best ERP will help your business grow smoothly and stay competitive.

Frequently Asked Questions

Industry-specific ERP software is made for transformer companies, so it fits your needs better, helps avoid mistakes, and makes it easier to follow industry rules and customer requirements.

ERP software automates quality checks and records every step, helping you meet industry standards and making it easy to pass audits or show proof of compliance when needed.

Implementation time depends on your business size and needs, but most ERP projects take a few weeks to a few months, including setup, training, and moving your data.