Quick Summary

Manufacturing ERP systems play a critical role in the digital transformation of the manufacturing industry. These systems streamline operations, enhance decision-making, and improve compliance, leading to better operational efficiency. By leveraging ERP for manufacturing, businesses can optimize resources and remain competitive in a rapidly evolving landscape.

Table Of Contents

Introduction

In today’s fast-paced manufacturing landscape, embracing digital transformation is no longer optional—it’s essential. Manufacturing ERP systems serve as the backbone of this transformation, offering tools to streamline workflows, optimize resource allocation, and improve decision-making. Businesses leveraging ERP systems for manufacturing enjoy enhanced visibility, operational efficiency, and compliance with industry standards, ensuring sustainable growth.

Key Takeaways

Manufacturing ERP systems streamline operations and reduce manual errors.

Real-time data and analytics empower better decision-making.

ERP solutions ensure compliance with industry regulations.

Scalability and customization are vital for ERP software selection.

Future trends include AI, IoT, and cloud-based ERP for enhanced efficiency.

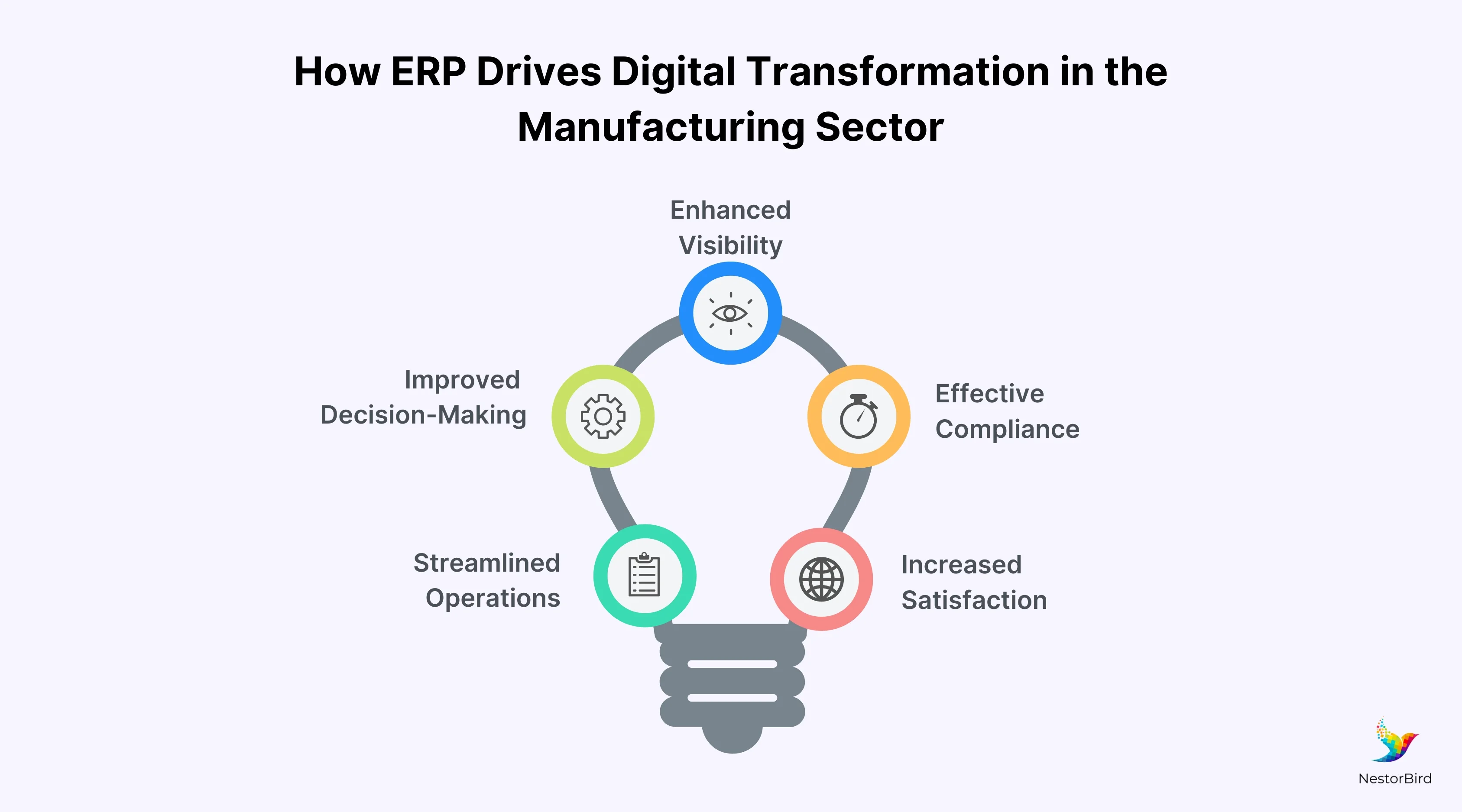

How ERP Drives Digital Transformation in the Manufacturing Sector

Streamlined Operations

Manufacturing ERP systems centralize data and automate repetitive tasks, reducing manual errors and increasing operational efficiency. From production planning to inventory management, these systems ensure seamless workflows, enabling manufacturers to meet deadlines and maintain quality standards.

Improved Decision-Making

With real-time data and advanced analytics, ERP for manufacturing empowers stakeholders to make informed decisions. These insights allow businesses to identify inefficiencies, predict market trends, and allocate resources effectively, fostering agility in an ever-changing market.

Enhanced Visibility

ERP manufacturing solutions provide end-to-end visibility across the supply chain, helping businesses track production processes, inventory levels, and delivery schedules. This transparency improves collaboration and enables proactive problem-solving.

Effective Compliance

Adhering to regulatory requirements is critical in manufacturing. ERP manufacturing software ensures compliance by standardizing processes, maintaining accurate records, and automating reporting. This reduces the risk of non-compliance and potential fines.

Increased Satisfaction

A well-implemented manufacturing ERP system enhances customer and employee satisfaction. Customers benefit from timely deliveries and consistent quality, while employees experience smoother workflows and better resource availability.

How to Choose the Right Manufacturing ERP Software

Scalability and Flexibility

As your business grows, so do its operational needs. The best ERP for manufacturing adapts to changing requirements, ensuring long-term value. Look for systems that offer scalability and flexibility to support expansion.

Customization Options

No two manufacturing businesses are the same. Opt for ERP manufacturing software that allows customization to meet your unique needs. Tailored solutions ensure alignment with your business goals and processes.

Vendor Support

Reliable vendor support is crucial for successful ERP implementation. Partner with vendors who provide robust training, regular updates, and prompt customer service to ensure smooth operations.

Integration Capability

A powerful ERP system for manufacturing seamlessly integrates with existing tools and software, such as CRM and supply chain management systems. This ensures a unified platform for all business operations, reducing inefficiencies.

Future Trends of Manufacturing ERP Solutions

The evolution of manufacturing ERP systems is shaping the future of the industry. Integration of artificial intelligence (AI) and machine learning (ML) enables predictive analytics and smarter decision-making. Cloud-based ERP solutions are becoming the norm, offering scalability, real-time data access, and cost efficiency. Additionally, IoT-enabled ERP systems enhance connectivity, providing deeper insights into machine performance and production efficiency. These advancements position ERP as a central force in driving innovation, adaptability, and growth in manufacturing businesses.

Conclusion

Manufacturing ERP systems are at the forefront of digital transformation, revolutionizing how manufacturers operate. From enhancing operational efficiency to improving compliance and decision-making, ERP solutions offer unparalleled benefits. Make an ERP Work for Your Small Business and Medium Enterprise, investing in the right manufacturing ERP software can pave the way for sustained success, enabling your organization to thrive in a competitive landscape.

Frequently Asked Questions

ERP plays a pivotal role in digital transformation by centralizing data, automating workflows, and providing insights for informed decision-making.

Digital transformation in manufacturing involves adopting advanced technologies, such as ERP systems, to enhance efficiency, visibility, and competitiveness.

Key benefits include improved operational efficiency, better decision-making, compliance with regulations, and enhanced customer satisfaction.

Begin by assessing current operations, identifying inefficiencies, and selecting a suitable ERP system for manufacturing to address these gaps.

Costs vary based on the scale of transformation, technology adoption, and specific business needs. Investing in ERP software for manufacturing is a significant step in this journey.