Quick Summary

It is important to use ERP software to increase operational efficiency. By combining the main business functions In one system, the ERP solution will help improve the cost reduction process and increase productivity. Learn that ERP software can help all sizes to increase efficiency. Improve decisions And how to help lead the competitors.

Table Of Contents

Introduction

The manufacturing sector is continuously under pressure to adapt to the needs of the market that changes all the time. To improve the efficiency of production and reduce operating costs. The manufacturer wants ERP software is an important tool for companies that want to improve operations and have a competitive advantage. Offer an integrated solution for managing various aspects of production by combining important business processes such as inventory, supply chains and production management.

Key Takeaways

Manufacturing ERP Software integrates key business functions into one platform.

ERP systems improve productivity, decision-making, and efficiency.

Customizable ERP solutions are scalable to accommodate business growth.

Effective ERP implementation requires careful planning and customization.

Nestorbird offers tailored ERP solutions for manufacturing businesses.

Manufacturing ERP Software

Manufacturing ERP software is designed to deal with the precise challenges confronted by means of producers, assisting them optimize workflows, beautify data visibility, and make informed selections. By consolidating disparate systems into one unified platform, Manufacturing ERP Systems facilitate better teamwork between departments, reduce data errors, and rationalise business processes.

In a manufacturing surroundings, wherein precision and performance are paramount, ERP structures offer actual-time get right of entry to to facts, enabling corporations to make brief choices based totally totally on updated information. These systems integrate modules for manufacturing scheduling, inventory manipulate, procurement, and order control, making sure clean operations throughout all stages of manufacturing.

Moreover, with the ability to be tailored to the specific dreams of different manufacturing sectors, Manufacturing ERP Systems offer scalable answers that broaden alongside your business.

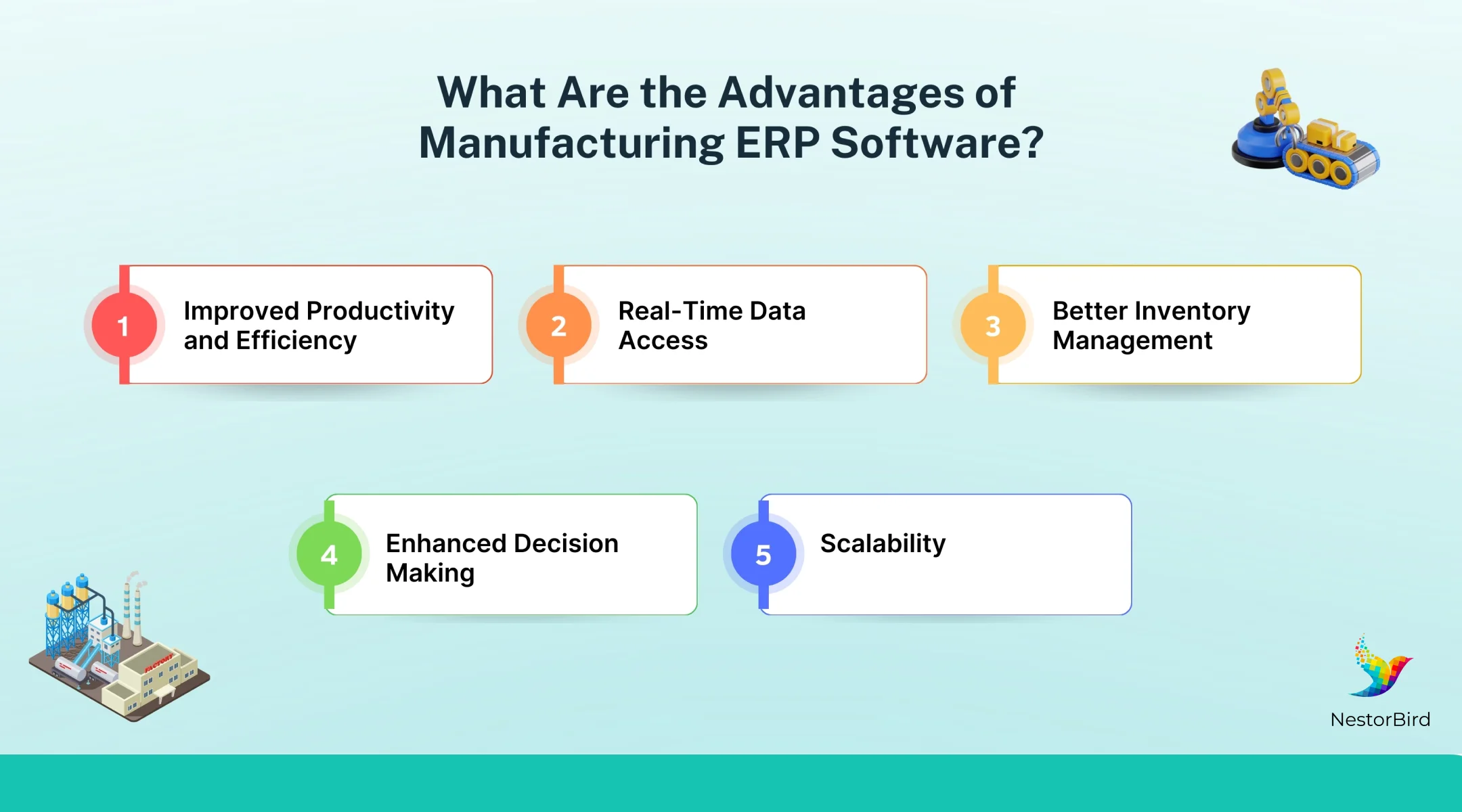

What Are the Advantages of Manufacturing ERP Software?

There are severa advantages of integrating Manufacturing ERP into your commercial enterprise operations. These advantages can substantially enhance the performance of your production manner, resulting in value financial savings, more suitable productiveness, and higher patron satisfaction.

1. Improved Productivity and Efficiency

By automating manual tasks, ERP systems reduce the time spent on administrative work, allowing employees to attention on extra strategic tasks. This outcomes in higher efficiency and productiveness across the company.

2. Real-Time Data Access

ERP systems provide actual-time facts on stock stages, production schedules, and order statuses, enabling corporations to make informed selections quickly and keep away from bottlenecks.

3. Better Inventory Management

With correct, real-time inventory records, manufacturers can keep away from stockouts and extra stock. This leads to optimized stock ranges, lower sporting expenses, and better coins glide control.

4. Enhanced Decision Making

Through centralized data and machine analytics, IRP helps resolve practical decisions with IRP software management that reduces beneficiary turnover, reduces administrative costs and satisfies customers the greater.

5. Scalability

As your business increases just as much as the ERP software. You can expand the new market or add new features, you can take the complex increase without the ERP system working.

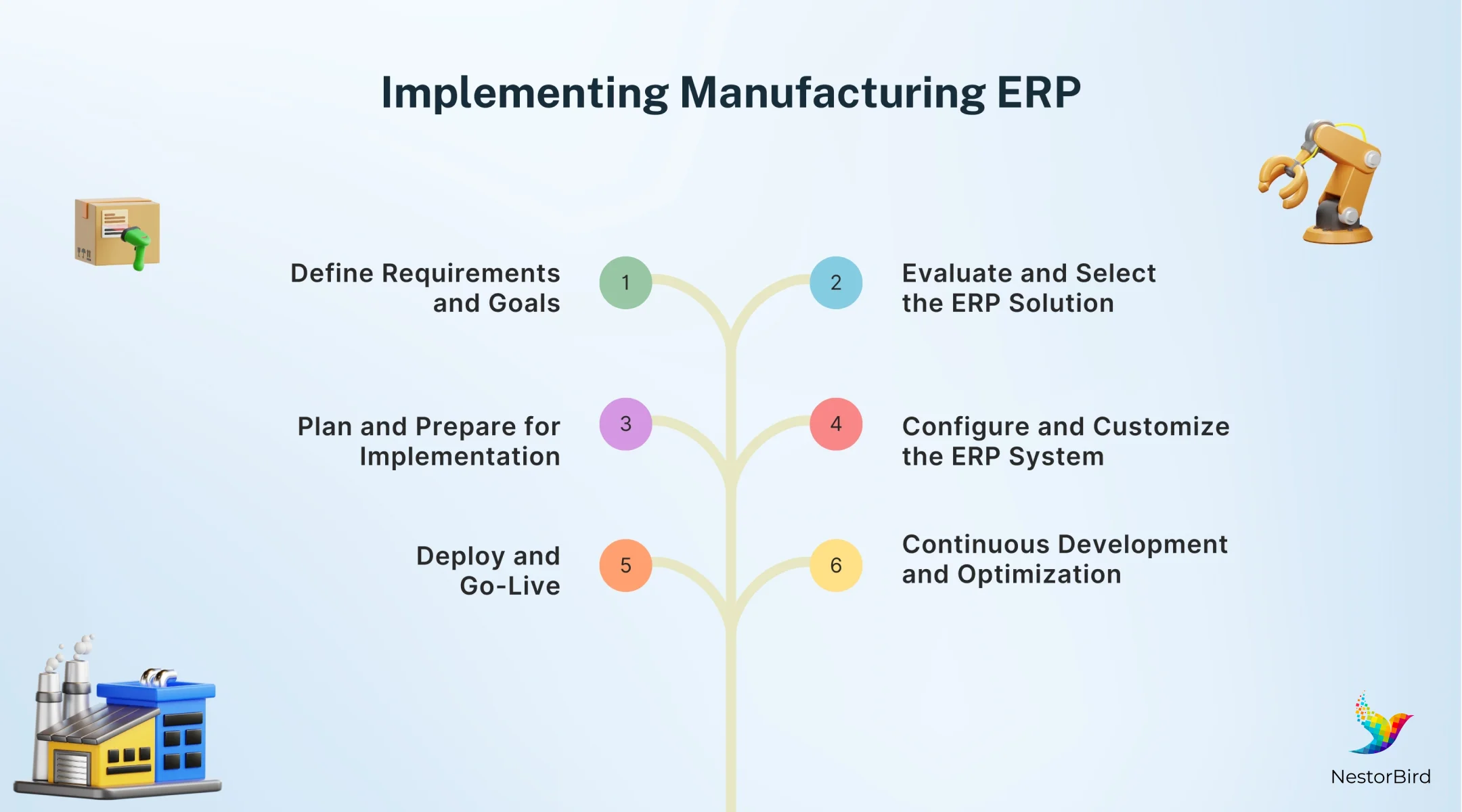

Implementing Manufacturing ERP

Implementing Manufacturing ERP Systems is a strategic process that requires careful planning, goal setting, and customization. Here’s a breakdown of the key steps involved in successfully adopting an ERP solution:

Define Requirements and Goals

Before you start selecting an ERP solution, it’s crucial to define your business’s specific requirements and set clear goals. This step will help you identify what features are essential for your business, such as inventory management, production scheduling, or order tracking.

Evaluate and Select the ERP Solution

Once your requirements are defined, evaluate various ERP options based on functionality, ease of use, and compatibility with your existing systems. Look for solutions that align with your business goals and industry needs.

Plan and Prepare for Implementation

Successful ERP implementation requires thorough planning. Work with your ERP vendor to develop an implementation roadmap, outlining timelines, budgets, and key milestones.

Configure and Customize the ERP System

Many ERP systems are customizable, allowing you to tailor them to your business’s unique processes. Configure the system to meet your specific needs, whether it’s adjusting workflows or adding custom features.

Deploy and Go-Live

After testing the system and ensuring everything works as expected, deploy the ERP system across your organization. A smooth go-live process is crucial for minimizing disruptions.

Continuous Development and Optimization

ERP systems require continuous optimization to ensure they evolve with your business. Regular updates, performance monitoring, and adjustments will help you maximize the value of your ERP solution.

Why Choose Nestorbird for Your Manufacturing ERP Solution?

The key of the construct that provides the erp gives the full capability of the erp is to be opened by the key. Nestorbird offers a broad range of erp solutions that can adapt to the needs of architects, without expectations of scale or industry. During the process and then, with expert support, Nestoorbard ensures that your erp decisions give you what you need for longevity. Nestoorbard has expanded their business in the construction departments. Here’s one such case study of a Marble Manufacturing Industry on Youtube -

Final Thoughts

ERP software that uses production as a game change for business that wants to increase efficiency and drive growth. A variety of functions such as inventory management, production planning and financial reporting to one system, ERP software helps manufacturers to increase operating efficiency, reduce costs and improve decisions, whether you are a manufacturer. Small or large organizations, ERP solutions can deliver long -term benefits. In addition, it can be confident that the business is successful in the market that is increasingly competitive.

Frequently Asked Questions

The ERP system works normally automatically. Provides real-time access to information; improves work procedures Help employees focus on value-added activities and ultimately increase work efficiency.

Yes, ERP software can help manufacturers track energy usage, waste production, and other environmental metrics. This enables more sustainable manufacturing practices.

Key features include inventory management, production planning, supply chain management, order processing, and reporting and analytics.

Absolutely! ERP systems are scalable, allowing small manufacturers to implement solutions that grow with their business needs.