Quick Summary

ERP software for manufacturing is essential in 2025 for streamlining processes, improving productivity, and ensuring profitability. With features like inventory tracking, real-time analytics, and compliance management, ERP systems for manufacturing are the ultimate solution for overcoming industry challenges and staying competitive.

Table Of Contents

Introduction

An ERP system is a comprehensive software solution designed to manage and integrate core manufacturing processes. These include production planning, inventory management, supply chain coordination, and financial oversight. ERP systems provide manufacturers with real-time insights and data-driven decision-making capabilities, ensuring seamless collaboration and efficient operations.

Key Takeaways

ERP software is vital for manufacturing businesses in 2025 to streamline operations, enhance productivity, and improve profitability.

Modern ERP systems address critical challenges like inventory mismanagement, regulatory compliance, and disconnected operations.

Advanced features like AI-driven analytics, real-time monitoring, and automation ensure scalability and efficient decision-making.

The integration of emerging technologies like IoT and machine learning makes ERP systems indispensable for staying competitive in a dynamic market.

Implementing ERP software now prepares manufacturers to overcome industry challenges and achieve sustainable growth in the future.

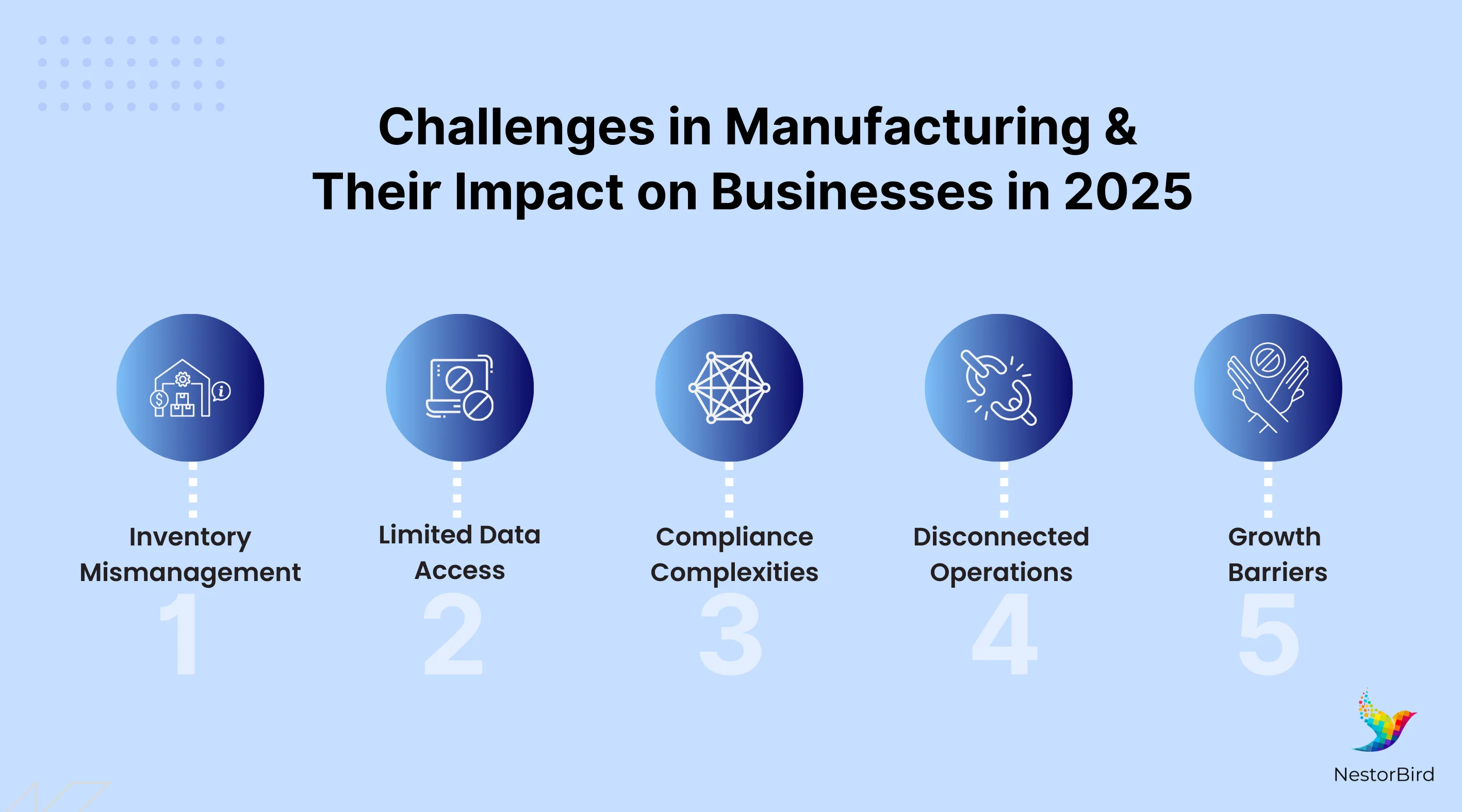

Challenges in Manufacturing & Their Impact on Businesses in 2025

Inventory Mismanagement: In 2025, precision in inventory management is more critical than ever. With global supply chain disruptions becoming a norm, maintaining accurate stock levels is vital to avoid delays and excessive holding costs. Modern ERP manufacturing systems provide advanced tools for real-time inventory tracking, automated alerts, and predictive analytics to ensure businesses are always prepared.

Limited Data Access: Without real-time insights, manufacturers risk making decisions based on outdated information. ERP systems now offer advanced data visualization and real-time dashboards that enable manufacturers to respond swiftly to changing market dynamics.

Compliance Complexities: Stricter regulations in 2025 demand more robust compliance strategies. Manual tracking of compliance requirements is no longer feasible. ERP systems ensure manufacturers stay compliant by automating regulatory processes, providing real-time updates on policy changes, and generating audit-ready reports.

Disconnected Operations: In an era of digital transformation, fragmented operations hinder growth. Disconnected departments lead to inefficiencies, errors, and communication gaps. ERP software in 2025 creates an integrated ecosystem that connects all business functions, fostering collaboration and transparency across the organization.

Growth Barriers: Legacy systems struggle to adapt to the evolving demands of 2025. Manufacturers aiming for scalability face limitations in outdated technologies. ERP systems are designed with scalability in mind, allowing businesses to handle increased workloads, expand operations, and seamlessly adopt emerging technologies like IoT and AI.

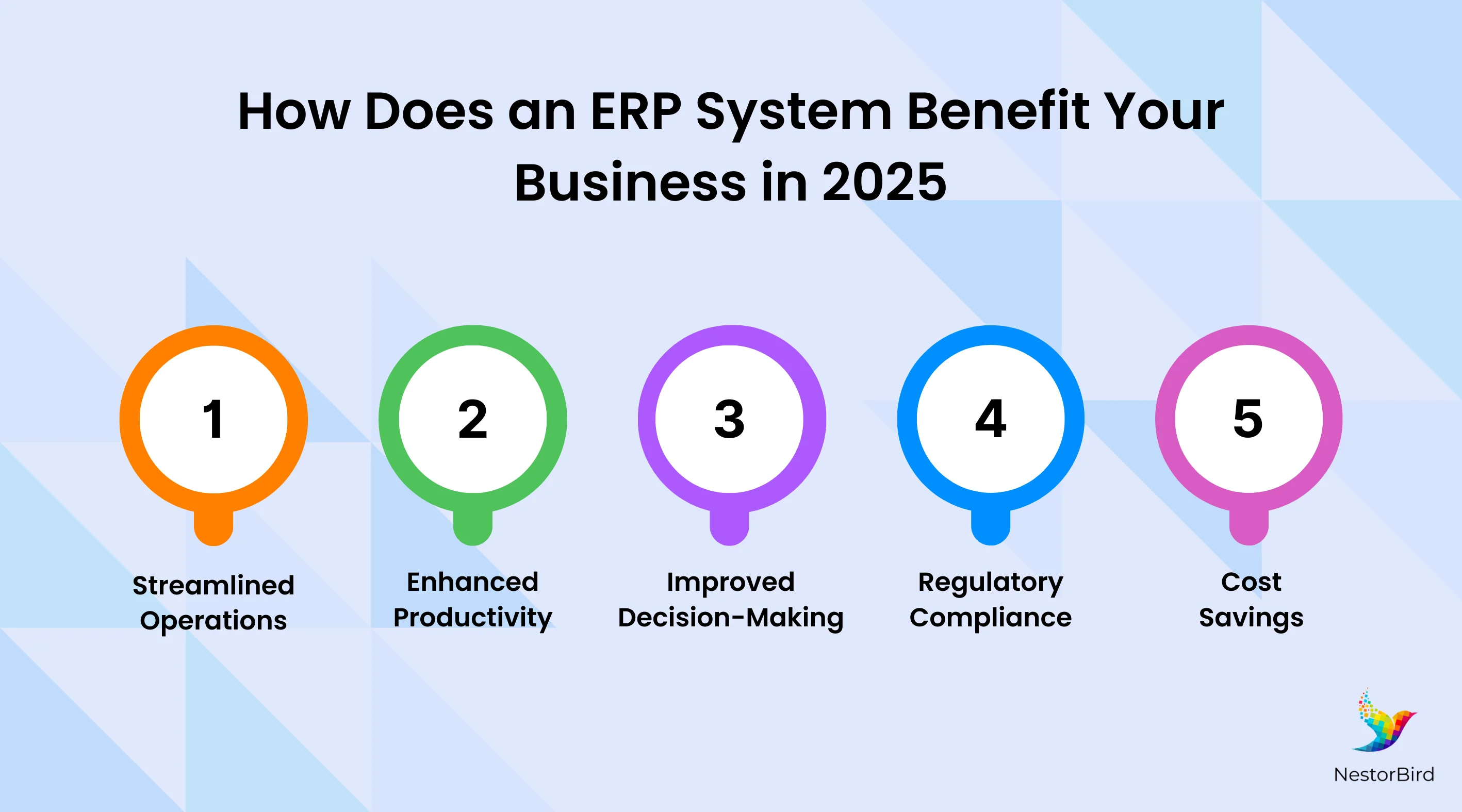

How Does an ERP System Benefit Your Business in 2025?

Streamlined Operations: ERP systems have evolved to integrate advanced functions like artificial intelligence driven production planning, real-time inventory tracking, and automated accounting into a unified platform. This significantly reduces redundancies and optimizes workflow efficiency.

Enhanced Productivity: Automation continues to advance, taking over time-consuming tasks such as scheduling and reporting. This allows employees to focus on innovative, high-impact activities, driving productivity to new heights.

Improved Decision-Making: With access to sophisticated, real-time data analytics and predictive tools, businesses in 2025 can make informed decisions quickly. These capabilities help manufacturers adapt to ever-changing market demands with precision.

Regulatory Compliance: Compliance will become more complex in 2025 with stricter global standards. ERP software now offers enhanced compliance modules, including automated document generation, AI-driven monitoring, and instant regulatory updates, ensuring businesses stay ahead.

Cost Savings: Advanced ERP systems in 2025 use machine learning to identify cost-saving opportunities, from reducing material waste to optimizing resource allocation. These systems also minimize downtime through predictive maintenance features, further improving profitability.

Why 2025 is the Right Time to Implement ERP Software

In 2025, the manufacturing landscape is set to undergo transformative changes, making it the ideal time to implement ERP software. The rapid advancement of technologies such as artificial intelligence (AI), the Internet of Things (IoT), and machine learning is revolutionizing how businesses operate.

Modern ERP solutions are now equipped to seamlessly integrate these technologies, offering manufacturers enhanced capabilities like predictive analytics, real-time monitoring, and intelligent automation. These features streamline processes and provide insights that drive smarter decision-making.

The intensifying competition in the manufacturing sector further underscores the necessity of adopting ERP software. As customer expectations rise and markets become more dynamic, operational efficiency and customer satisfaction are critical differentiators.

An ERP system enables manufacturers to optimize workflows, reduce downtime, and respond swiftly to market demands, ensuring they maintain a competitive edge.

Conclusion

Implementing ERP software for manufacturing is an investment in the future of your business. It streamlines processes, reduces costs, and enables manufacturers to meet industry demands with agility and precision. With ERP systems, manufacturers can stay ahead of the competition, ensure compliance, and achieve sustained growth. Start your journey toward efficiency and profitability today.

Frequently Asked Questions

ERP systems streamline processes, reduce inefficiencies, and provide valuable insights to help businesses thrive.

It prepares businesses to adapt to market changes, improve productivity, and ensure compliance with evolving regulations.

Features such as inventory management, real-time analytics, and regulatory compliance tools are highly sought after.

Yes, ERP solutions are scalable and can be tailored to fit the needs of businesses of all sizes.

By automating routine tasks, providing real-time insights, and improving workflow coordination.

It offers data-driven analytics and comprehensive reporting tools to guide strategic decisions.

ERP systems address inventory mismanagement, compliance issues, and operational silos effectively.