Quick Summary

Investing in a manufacturing ERP system can streamline operations, improve efficiency, and boost profitability for manufacturing industries. However, ERP software costs vary based on factors like company size, customization, and hosting. This guide explores ERP pricing models, expected costs, and budgeting tips to help manufacturing industries make a strategic ERP investment.

Table Of Contents

Introduction

For manufacturing industries focused on optimizing efficiency, reducing costs, and increasing profitability, manufacturing ERP systems have become essential. A manufacturing ERP system integrates core functions like inventory, production, supply chain, and finance into a single, cohesive business management solution. However, implementing an ERP manufacturing system is a significant investment, and ERP software costs vary widely.

This guide will help you understand the key factors impacting the costs of manufacturing ERP systems and provide budgeting insights to help ERP for manufacturing businesses make informed decisions.

Key Takeaways

Manufacturing ERP systems are tailored to handle complex processes, leading to higher costs compared to generic ERP.

ERP pricing varies by business size, with smaller manufacturers paying less than large enterprises.

Customization, data migration, and ongoing support are key cost factors for ERP implementation.

Cloud-based ERP options have lower upfront costs, while on-premise ERP offers greater control.

Budgeting for ERP involves planning for initial, ongoing, and user-related expenses to ensure a sustainable investment.

Why Manufacturing ERP Systems Are More Expensive — But Worth the Investment

1. Why Does Manufacturing ERP Cost More?

Manufacturing ERP systems provide specifically for the complex needs of manufacturing industries, including inventory tracking, production scheduling, quality control, and supply chain management. Due to these specialized requirements, ERP manufacturing systems often include advanced features and customizable ERP systems that drive up costs. Additionally, manufacturing ERP systems process large datasets and require robust support and real-time updates, further increasing costs compared to generic ERP.

2. What Return Can You Expect From an ERP Investment?

While manufacturing ERP solutions are a substantial investment, they can bring considerable returns through streamlined processes, minimized downtime, improved data accuracy, and better resource management. ERP for manufacturing businesses reduces errors, improves supply chain performance, and ensures regulatory compliance, leading to greater productivity and profitability.

ERP Price Estimates

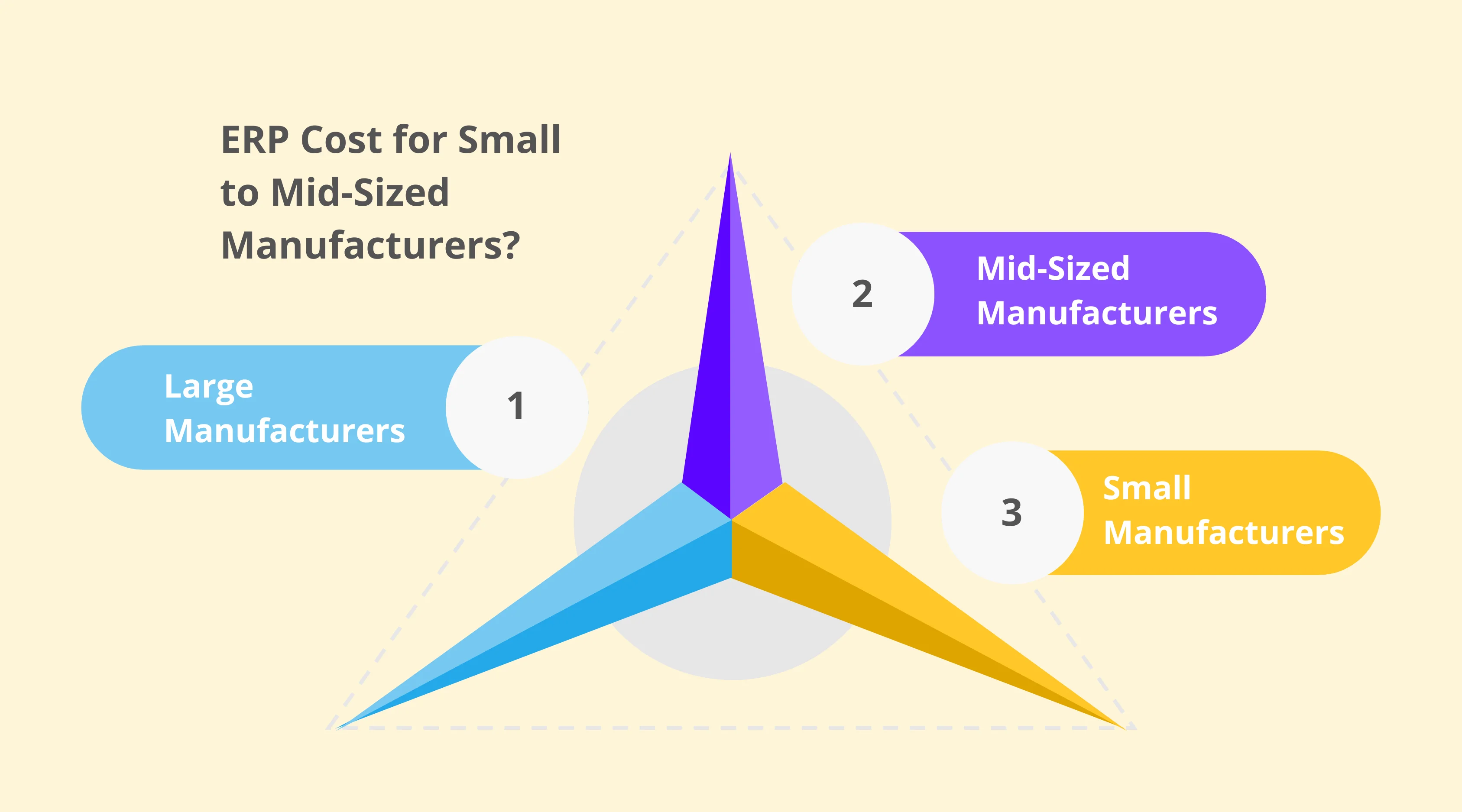

1. How Much Does ERP Cost for Small to Mid-Sized Manufacturers?

ERP software costs for smaller manufacturers are typically more manageable, especially with cloud-based or subscription models that reduce upfront expenses. Here’s a breakdown of ERP costs by business size:

Small Manufacturers: Costs range from $10,000 to $50,000 for initial setup, with monthly expenses from $1,000 to $5,000 depending on features and user count.

Mid-Sized Manufacturers: Initial costs vary between $50,000 and $250,000, especially if more customizable ERP systems are required.

Large Manufacturers: For large-scale manufacturing industries, ERP implementation can start at $500,000 and may reach $1 million, depending on customization, hosting, and integration needs.

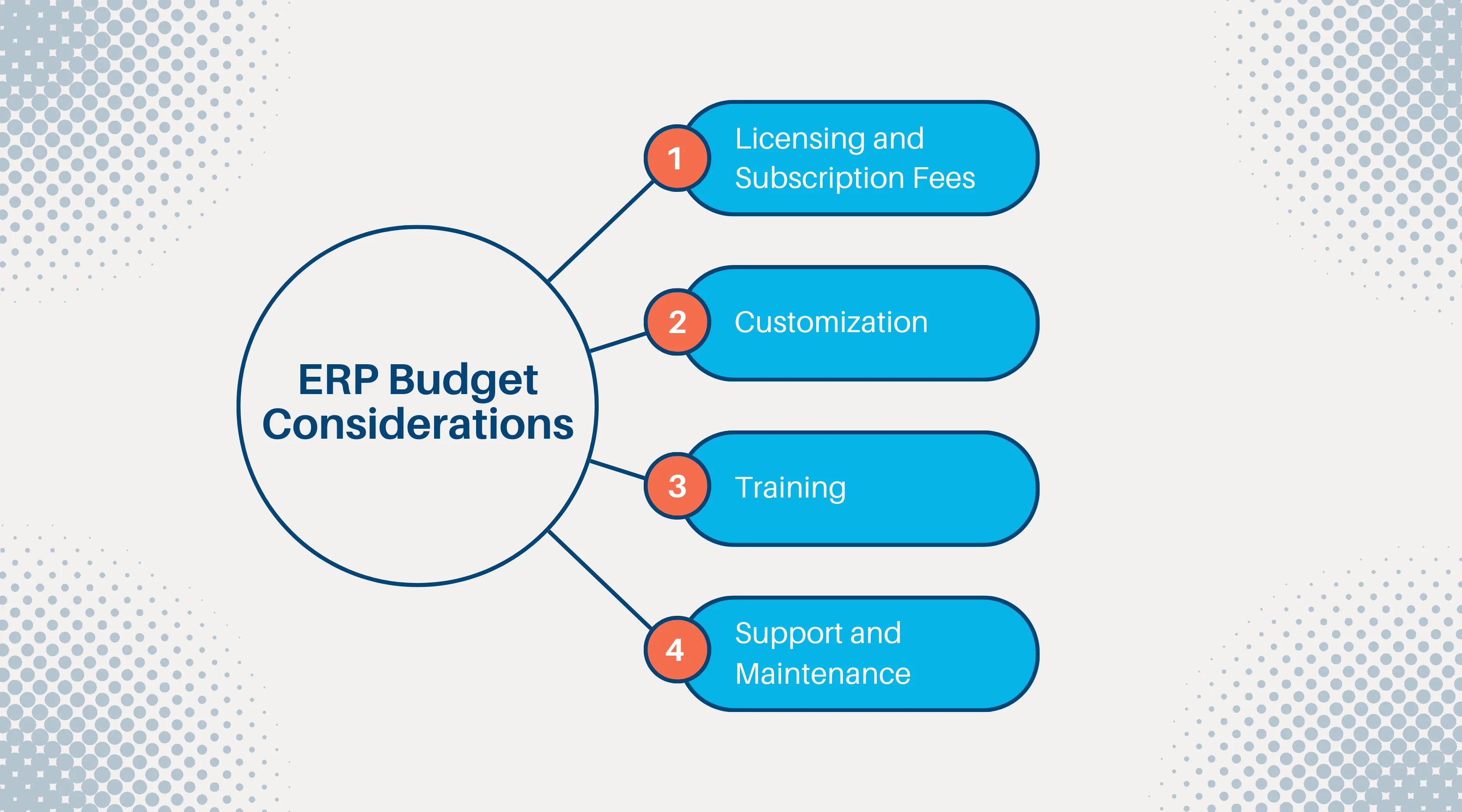

2. ERP Budget Considerations

When budgeting for manufacturing ERP systems, ERP manufacturing system costs include not only the software but also several additional factors:

Licensing and Subscription Fees: Subscription-based ERP for manufacturing models require ongoing fees, while perpetual licenses involve a one-time payment with annual maintenance fees.

Customization: Tailoring a customizable ERP system to meet specific needs increases initial costs, common for manufacturing industries with unique processes.

Training: Training employees on the manufacturing ERP is essential and often priced by training hours and user count.

Support and Maintenance: Regular support and maintenance are necessary, adding to ongoing ERP software costs.

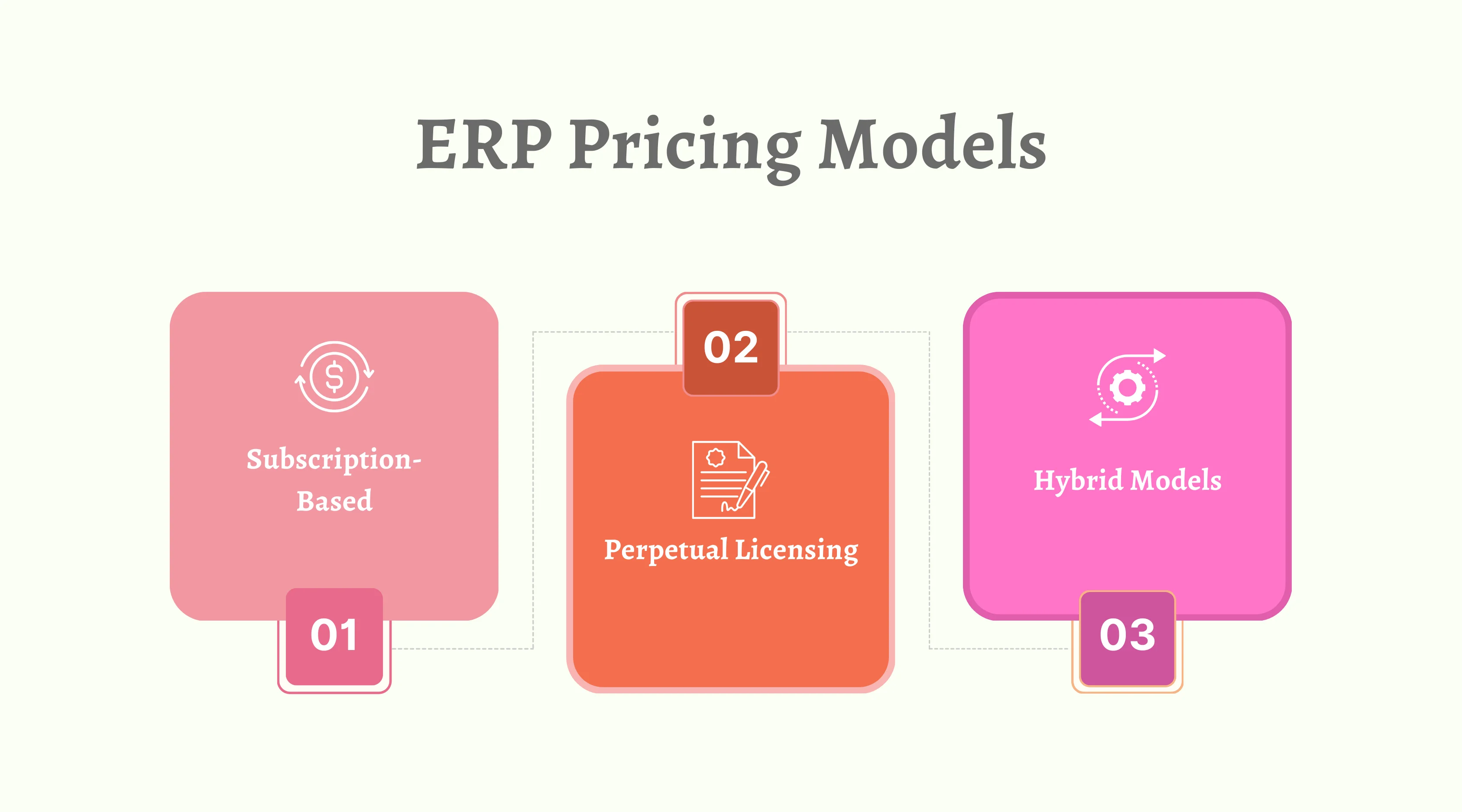

3. ERP Pricing Models

Subscription-Based (SaaS): Known as Software-as-a-Service (SaaS), this model charges monthly or annual fees and is hosted in the cloud, reducing upfront costs and including regular updates. ERP for manufacturing businesses often prefer this model due to flexibility and lower initial expenses.

Perpetual Licensing: This one-time payment model involves a higher initial cost but can lower long-term ERP software costs. However, it may require a substantial upfront investment, suitable for manufacturing industries that prefer full ownership and control.

Hybrid Models: Hybrid models combine elements of subscription and perpetual licensing, offering manufacturing industries the flexibility to choose the best fit for their ERP manufacturing system requirements.

4. ERP Hosting and Infrastructure

Cloud-Based ERP: Cloud-based ERP manufacturing systems eliminate the need for in-house infrastructure and have lower setup costs. These manufacturing ERP systems charge ongoing fees but generally lower initial costs, ideal for smaller or mid-sized manufacturing industries.

On-Premises ERP: With on-premise ERP for manufacturing, businesses host the software on their own servers. While this model requires substantial upfront infrastructure investment, it offers greater control over data, often preferred by larger manufacturing industries.

How to Budget for an ERP Project

1. Initial Costs

Data Migration: Transferring data to your new ERP manufacturing system is time-consuming and may require reformatting, adding to the cost.

Customization and Integration: Customizing the manufacturing ERP system to integrate with existing tools and workflows often adds significant expense.

2. Ongoing Costs - Updates and Support

Regular updates, support, and feature upgrades keep the ERP manufacturing system running smoothly, contributing to ongoing costs.

3. Key Factors Affecting ERP Pricing

Number of Users: Cost scales with the number of users in the manufacturing ERP system.

Licensing Type: SaaS models charge ongoing fees, while perpetual licenses have one-time costs.

Deployment Method: Cloud-based ERP incurs monthly fees, while on-premise solutions require higher initial costs.

Add-On Modules: Modules like CRM or MES raise costs but add value to the ERP for manufacturing.

Implementation: Initial setup and deployment add to the total erp software cost.

Training and Support: Effective training ensures smooth use, adding initial and ongoing costs.

Hardware Upgrades: Modern manufacturing ERP systems may need hardware upgrades for optimal performance.

Planning for these elements creates a realistic ERP budget, ensuring manufacturing industries are prepared for both short-term and long-term costs.

Frequently Asked Questions

Selecting an ERP involves understanding your needs, ensuring the ERP manufacturing system aligns with workflows, and considering future scalability.

Choose vendors with manufacturing ERP experience and a strong support record. Case studies and testimonials are helpful.

Compare providers, request demos, explore pricing models, and negotiate bundled services or long-term deals for potential savings.

Cloud ERP stores data on remote servers, accessible via the internet, offering flexibility and often lower ERP software costs.

Key factors include business size, customization, hosting, licensing fees, and support costs.

Yes, options include subscription-based, perpetual licensing, and hybrid models, each suited to different needs and budgets.

Customization and integration in an ERP manufacturing system increase initial setup costs and may require extra resources.

Final Thoughts

Investing in the right manufacturing ERP system can transform your operations, boosting efficiency, productivity, and profitability. However, understanding the full ERP software cost—from initial setup, licensing, and customization to maintenance—is essential for informed decisions. Assess your business needs and explore Best ERP options to ensure successful ERP implementation tailored to manufacturing industries.