Quick Summary

This guide explains how ERP for transmission industry helps transformer manufacturers run smoother operations. Learn how the right ERP software for transformer industry improves planning, inventory, and quality control.

Table Of Contents

Introduction

No matter the industry, when you streamline your operations and business functions, it can greatly improve your efficiency and chances of growth and scale. In the transformer industry, managing day-to-day production, keeping track of many different parts, and meeting deadlines can be tough. Many businesses rely on old methods and paperwork, which easily causes mistakes and wastes time. Luckily, using ERP for transmission industry can help make everything more organized. This blog post will show you how ERP software for transformer industry and simple tools like the right software can make work easier, reduce errors, and help your business become more efficient.

Key Takeaways

ERP for transmission industry helps improve production planning and reduces delays.

Using ERP software for transformer industry ensures better inventory and batch tracking.

Industry-specific ERP software supports quality control and compliance easily.

Real-time data from industrial ERP solutions aids faster and smarter decisions.

Choosing the best ERP software for transformer industry saves time and cuts errors.

Operational Bottlenecks in Transformer Production- The Many Current Challenges

In the transformer industry, there are many day-to-day challenges that slow down production. Factories often depend on manual job card sign-offs, which causes delays and mistakes, and moreover, handling defective stock is hard, especially when it is not tracked properly, and working with different factory sites makes it even tougher to coordinate everything.

The bill of materials here is often complex and can be hard to manage without a proper system, so getting needed raw materials like copper or steel on time is a big challenge because procurement is not always regular. With these problems, there is a big lack of real-time updates, making it hard for managers to see where each job stands and to keep up with delivery deadlines.

That’s why many people in the industry want to know how to match production with dispatch schedules or how to stop errors in batch tracking. Using suitable ERP software and the best ERP software for transformer industry can solve these problems, making work smoother and reducing costly mistakes.

Also check out How ERP Enhances Efficiency Compliance Pharma.

ERP for Transmission Industry: The Best Solution of Smart Manufacturing

If you are a transformer industry leader or just getting started with your business, it is a great idea to invest in the right, best suitable, and efficient ERP software for transformer industry that is specific and catered to your unique business, which can solve and simplify your everyday business functions.

The ERP for transmission industry offers many useful tools to plan production specifically for different transformer types like power, distribution, or specialty transformers. It helps keep inventory organized with batch-wise tracking and provides pre-built templates for tasks like coil winding, oil filling, and tank assembly.

Check out some of the Top Retail ERP Software Features.

With the right software integrated, work orders can be generated and tracked instantly, speeding up the process and reducing mistakes. Overall, this kind of ERP brings automation and helps predict future needs, making the whole manufacturing process smoother and more efficient.

How ERP Software for Transformer Industry Enhances Plant Efficiency and Streamlines Production

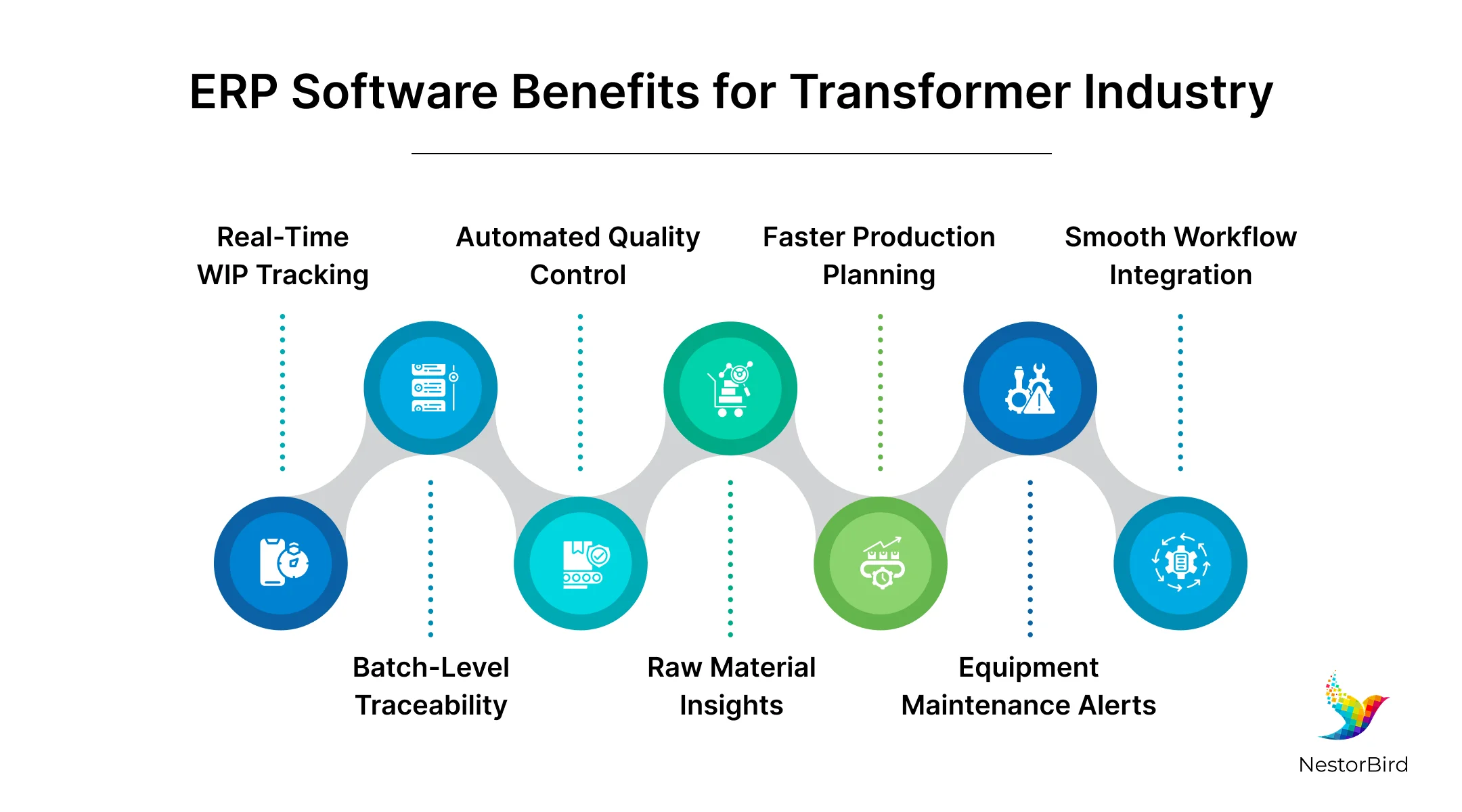

Improved Batch Traceability For Your Business: When you choose a modern ERP software for transformer industry, it offers clear tracking of all batches produced. This helps managers know the exact status of each batch from start to finish. It reduces mix-ups and ensures that every part meets quality standards, leading to better control over production.

Better and Efficient Quality Control: Using the best ERP software, manufacturers can automate quality checks at each step of production, which in turn reduces manual errors and keeps the product standard consistent. The system also stores test results, which helps during audits and maintains compliance with industry rules.

Streamlined Equipment Maintenance: These industrial ERP solutions include tools that schedule and track equipment maintenance automatically. This stops unexpected breakdowns and keeps production running smoothly, plus regular maintenance alerts help save time and repair costs.

Real-Time Work-in-Progress (WIP) Tracking: With ERP software, companies can see live updates on the status of ongoing work. This real-time WIP tracking helps managers spot bottlenecks early and improve workflow efficiency, ensuring timely deliveries.

Here is why you should have an ERP Implementation Plan.

Automatic Alerts for Material Stockouts: The system sends automatic warnings before materials like copper or steel run low, which then prevents delay due to missing raw materials and supports continuous production without interruptions.

Digitized Transformer Testing Modules: Testing steps are fully digitized in industry-specific ERP software, reducing paperwork and data loss, and here the digitized modules ensure quick record-keeping and easy access to testing reports, improving accuracy and reducing time spent on manual data entry.

Shift From Spreadsheets to Industry-Specific ERP Software: Many transformer companies move away from manual tracking on spreadsheets to adopt industry-specific ERP software. This change saves significant time, reduces errors, and provides a single platform to manage production, inventory, and quality together, improving overall plant efficiency in the long run.

Industrial ERP Solutions: Proper Integration Across All Departments

Industrial ERP solutions help different departments in a transformer company work better together. For example, the sales, production, and invoice systems can connect in one place. This means once a sales order is made, the ERP automatically updates production and creates an invoice, saving time and avoiding errors.

Here, a centralized vendor system also helps in managing suppliers and sets automatic reorder points when raw materials are running low. You don’t need a full IT team to make changes, plus the system can be easily adjusted for different transformer products or SKUs over time, and is very useful as customer needs change.

That’s why using ERP for transmission industry gives companies more control, faster decision-making, and a more stable process. It supports both big and small teams in staying updated and handling daily work without stress. This is why more businesses are now trusting industrial ERP solutions to run their factories smarter and faster.

Know more about multi-carrier shipping software.

What Makes the Best ERP Software for Transformer Industry?

The best ERP software for transformer industry should be built specifically for transformer operations and not just modified from other industries, plus it must provide real-time analytics, helping leaders make fast and smart decisions.

The system should include tools for production and warehouse management, with functions like multi-level bill of materials handling, precise batch tracking, and integrated quality control, as these are features that many generic ERP solutions usually lack but are important to run your transformer business efficiently. So, a focus on these areas ensures smooth, simple, and effective management tailored for transformer businesses.

Closure Note

Using the right ERP for transmission industry can greatly improve how transformer companies work. It helps manage production, inventory, and quality more easily and reduces mistakes. With ERP software for transformer industry, businesses can save time and costs while growing smoothly. Choosing the best ERP software from NestorBird, made for this particular field, ensures your operations run well and adapt to changes.

Frequently Asked Questions

ERP helps schedule production based on orders, machine availability, and materials, reducing delays and ensuring efficient use of resources for transformer manufacturing operations.

It automates quality checks and logs all inspections digitally, helping maintain industry standards and reducing product defects in the transformer industry.

ERP software offers real-time dashboards and detailed reports on production, inventory, and finance, helping managers make fast and informed business decisions.