Facing issues in the manufacturing of electronics? No worries, we got you covered. We prersent you the best ERP software for electronics manufacturing: ERPNext. Get now and get your work done effectively

In the today’s era, electronics have become one of the most important part of our life. Electronics or electronic devices include all the devices which can control, communicate and process the information as well. The impact of electronics have become universal, virtually touching every part of contemporary life. From communication to healthcare, the need for electronics is everywhere. Hence, demand for electronics have also increased.

With the increasing demand of electronics, the electronic industries have achieved a great height of success. From smartphones and laptops to medical devices, electronics industry has attained its position in each and every field. But as the level of work increased, their challenges also increased to complete a particular task.

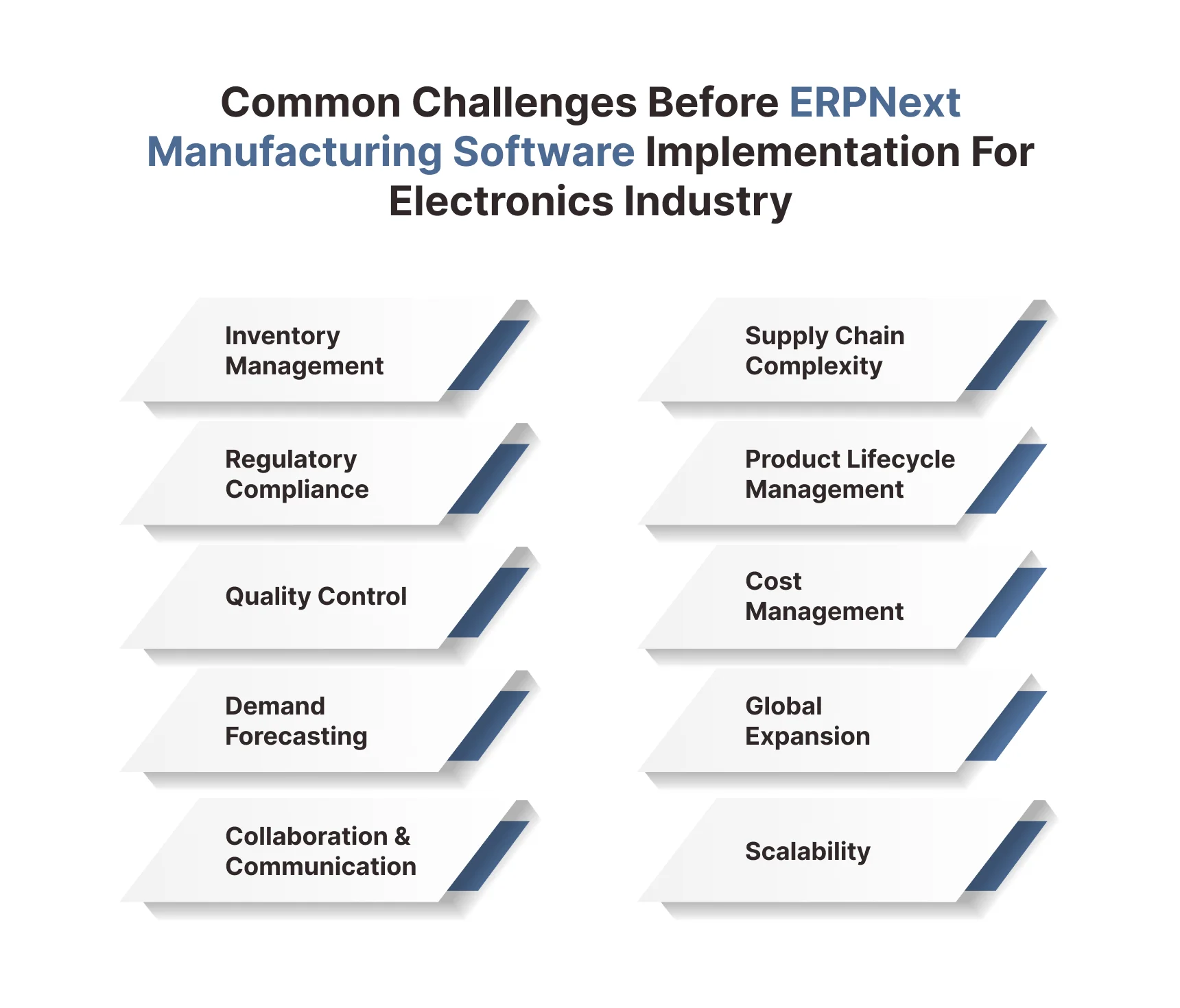

Following are some of the common challenges faced by the electrical and electronics manufacturing companies:

Common Challenges Faced by Electrical and Electronics Manufacturing Companies

Inventory Management

Electronic manufacturers have a vast inventory, due to which they face a lot of challenges to manage it. Poor inventory management can lead to poor production, increased costs and poor efficiency. Thus having an good inventory management is crucial.

Regulatory Compliance

The manufacturers need to follow some rules and regulations such as WEEE (Waste Electrical and Electronic Equipment) and RoHS (Restriction of Hazardous Substances). In addition to this, the manufacturers need to keep in mind about the safety and quality standards such as ISO, IEC and UL.

Quality Control

The manufacturers need to maintain a high quality standards in order to stand in the market. Any fault in the quality can lead the company to pay a huge loss and it also degrades the reputation of the company.

Demand Forecasting

Though demand forecasting is challenging but it is an essential part of the production. Demand forecasting refers to the prediction of future demand by analyzing several factors such as market trends and historic sales data. Inaccurate forecasting can lead to the excessive use of inventory or over usage of production costs.

Collaboration & Communication

Effective collaboration and communication is one of the important parts of any business. It involves coordinating with different teams and departments. A good communication helps the stakeholders to stay aligned, whereas lack of communication can lead to a bundle of misunderstandings.

Supply Chain Complexity

The supply chain involves multiple number of suppliers due to which it becomes highly complex. To manage this complexity robust systems should be present to track all the components and ensure timely deliveries.

Product Lifecycle Management

The work of Product Lifecycle Management (PLM) is to look after the entire lifecycle of a product, from designing to ejection. It becomes challenging as the upgradation of technologies is rapid and lifespan if product is short.

Cost Management

It is important for manufacturers to look upon the costs in order to have maximum profits. The manufacturers need to be very careful in the terms of overseeing production costs. The more accurate cost tracking is, the more informed financial decisions will be taken.

Global Expansion

Global Expansion is also filled up with challenges as it requires strategic planning and investment in various factors such as infrastructure, technology and talent. Manufacturers also need to adapt the marketing strategies in order to meet the regional requirements.

Scalability

Scalability refers to increase in the production capacity and manage large volumes of inventory. To do this, it is essential for the manufacturers to invest in scalable technologies, and robust infrastructure so that the company can adapt to changing market demands.

Presenting ERPNext Manufacturing Software as a Solution

To overcome all these challenges we present to you our ERPNext software. ERPNext is an open-source ERP solution for electronics manufacturing. It is the best ERP software for electronics manufacturing industry as it offers a suite of integrated modules that improves decision-making and enhance overall efficiency.

Following are the reasons you should opt for ERPNext for your problems:

Optimized Inventory management

ERPNext offers you the best features required for inventory management such as tracking of stock levels, automation of reorder points as well as optimization of stock management.

Managed Suppy chain

ERPNext helps in the optimization and structured management of Supply chain. It also reduce the time leads, increase the rates of fulfillment of orders and helps in increasing overall efficiency as well.

Ensured regulatory compliance

ERPNext ensures to have detailed records and compliance in adherence to regulatios and safety standards.

Product lifecycle management

ERPNext helps in PLM by enabling the manufacturers to track and manage the lifecycle of their product. It ensures that stakeholders obtain the latest information about the products.

Quality management

ERPNext offers the best quality control tools to allow the manufacturers to set the quality standards. Our software ensures that only the products that meet the quality standards set by the manufacturer are released in the market.

Cost optimization

ERPNext also provides you the latest costing tools that helps in tracking production costs. Additionally ,this software offers transparency which help the manufacturers to have better cost management.

Demand forecasting improved

ERPNext includes the tools required for demand forecasting that analyze historical data and market trends to predict the future demand. This helps the manufacturers to plan the production and manage inventory more effectively.

Supports global expansion

ERPNext supports global expansion by offering multi-currency transactions and compliance with international regulations.

Promotes communication & collaboration

Moreover ERPNext encourages collaboration. It provides a centralized platform where all the stakeholders can communicate and access the latest information about the product.

Scalability

ERPNext is highly scalable as it provides the manufacturers to add new functionalities whenever they want. ERPNext is an open-source software that can be customized as per the needs of the manufacturer.

How Can NestorBird Help Your Electronics Industry with ERPNext Manufacturing Software Implementation?

Here at NestorBird, we understand about the challenges that electronics industry faces. Our dedicated experts team is ready to design ERPNext in order to meet your needs. Our team ensures to provide you with optimal performance. We are here for you whenever you need us, from initial consultation to ongoing assistance.in addition to this if you partner with us, you will be getting a trustful supporter who will improve your inventory management and ensure regulatory compliance. We will help you to enhance your operations so that you can focus the ways to grow your business.

What makes us unique in the world of ERP:

24*7 Technical Support

Free ERP Demo

100+ Certified Developers

Fast and Easy ERP Implementation

Free ERP Business Consultation

Conclusion

To conclude with, ERPNext is a powerful tool to solve the challenges faced by electrical and electronics industry. By using ERPNext, you can enhance your productivity and maintain a top position in electronics market. Integrate ERPNext to upgrade your production process and stand out in your business.

If you are looking for the best ERPNext manufacturing software for your electrical and electronics industry, contact NestorBird experts at [email protected] or Call/SMS/Whatsapp at +91-9878990102 to book a free demo today!