Quick Summary

This blog explains how ERP for life sciences helps companies in pharmaceuticals and related fields overcome challenges. It covers compliance, supply chain, quality control, cost management, and growth support through efficient ERP solutions.

Table Of Contents

Introduction

There are different industries that need to follow some stringent, required, and important rules, regulations and compliances. The life sciences industry is one such field that focuses on improving health through science, including pharmaceuticals, biotechnology, and medical devices. Because of this, it faces many challenges in managing operations while staying up to date with strict regulations. In this blog post, we will look at how adopting an ERP for life sciences helps companies simplify their processes, meet rules, and solve common problems. We will also see how ERP life sciences solutions make work easier and improve overall efficiency in this complex industry.

Key Takeaways

ERP for life sciences helps follow strict rules and regulations.

Improves supply chain visibility and reduces delays.

Maintains quality and safety in production processes.

Protects sensitive business and patient data from risks.

Reduces costs and supports business growth.

How ERP Helps Life Sciences Companies Follow Rules and Regulations

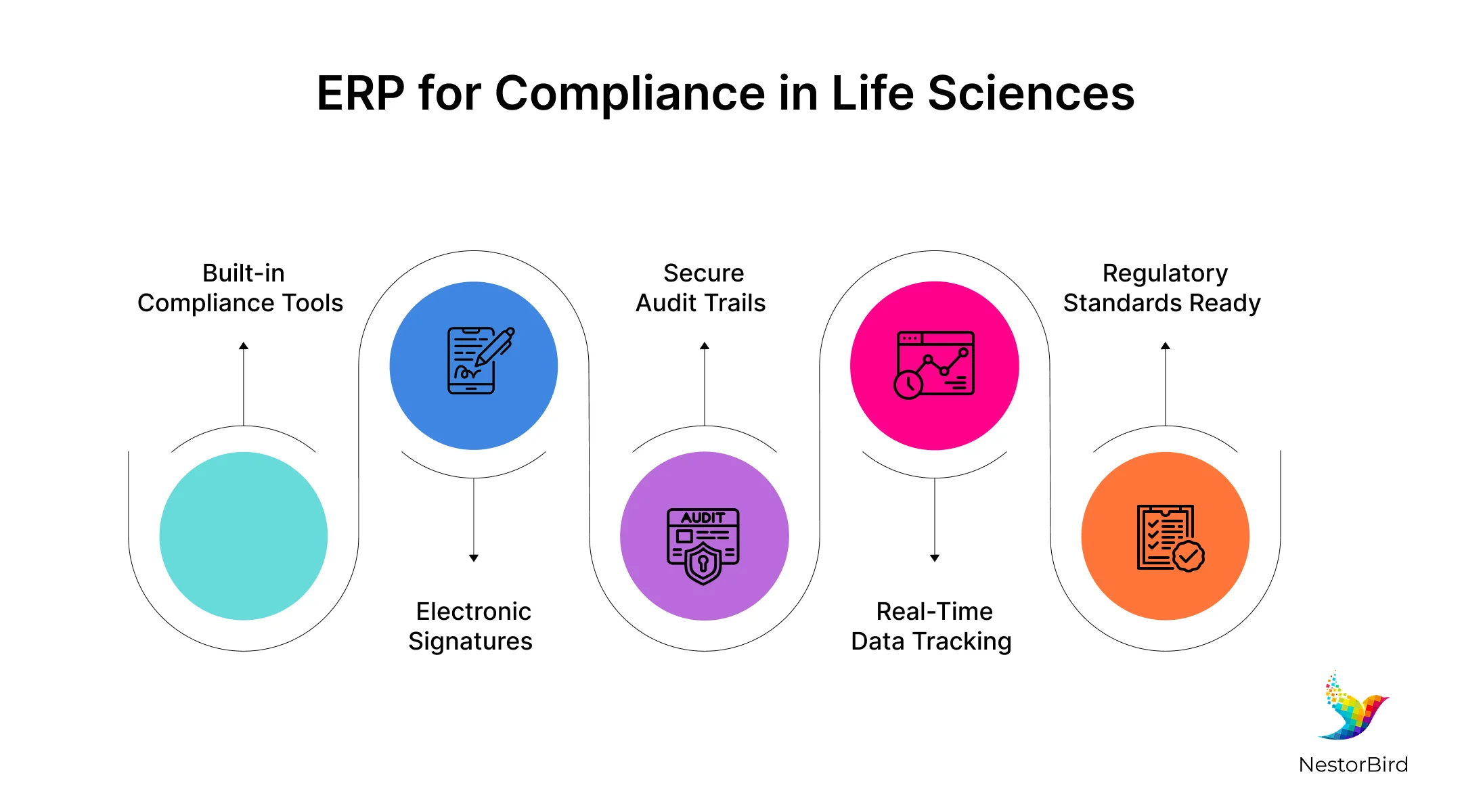

In the life sciences industry, businesses face strict and changing rules like FDA 21 CFR Part 11, EMA Annex 11, and GxP guidelines. These rules ensure that products like medicines and medical devices are safe and meet quality standards, and here the pharmaceutical ERP and life science ERP systems help companies follow these rules by providing built-in compliance features.

ERP life sciences support important tools such as electronic signatures, audit trails, and validation-ready processes that keep records accurate and secure. That’s why using these life sciences software solutions helps avoid mistakes that could lead to regulatory failures or costly product recalls, and the ERP systems make it easier for life sciences companies to stay compliant and protect patient safety.

Learn more about ERP for Pharmaceuticals Challenges and Benefits.

How ERP Improves Supply Chain and Inventory Management

When it comes to managing the various operations and functions of the business in the supply chain and inventory, the life sciences and pharmaceutical industries face many challenges. These include handling products that need special temperature controls (cold chain) and tracking every batch to ensure quality and safety.

ERP for pharma companies helps by giving real-time data and control over the whole supply chain. This means companies can see exactly where their products and materials are at all times.

So, managing complex inventories with different types and conditions becomes easier with life sciences software and ERP life science systems. These tools help in better forecasting, reducing waste, and improving the responsiveness of the supply chain, making the whole process more agile and efficient.

Let us check out more on ERP Implementation Plan.

Making Clinical Trials and Sample Tracking Easier with ERP

In this industry, a lot of resources are spent on main and important functions like clinical trials and sample management. One big challenge is keeping track of many samples used for testing and making sure they are handled correctly through long product lifecycles.

So here, using life science ERP helps by automating record-keeping and keeping all trial data in one place. This way, researchers can quickly access and manage the information they need without mistakes.

With life sciences software development, companies can reduce human errors and speed up trial processes. This makes managing samples more efficient, which is important for keeping trials running smoothly and meeting regulatory requirements. And, these software solutions help improve accuracy and save time during clinical trials, which benefits patients and companies alike. Here are the Top ERP Software Solutions.

Connecting All Business Systems into One Platform

For any business to work and function smoothly, without any delays or issues in any part of the process, it is important to have all systems connected and working together. In the life sciences industry, many companies use separate software for finance, manufacturing, quality control, and other tasks. This can cause problems when information is stored in different places, making it hard to share data and slowing down work.

So here a unified ERP for life sciences solution or software brings all these functions into one system. This helps teams work better together by sharing accurate, real-time information. Using life sciences software solutions that are integrated reduces errors, avoids repeated work, and keeps data consistent across departments. That's why, having one connected ERP system makes the entire business more efficient and helps life sciences companies respond faster to challenges.

How ERP Maintains Quality in Production

Maintaining proper and high quality really matters in this industry to make sure it complies and meets all safety standards. Pharmaceutical ERP systems help by controlling the production process and checking quality at every step. These systems enforce quality orders that guide when and how testing should happen during production.

They also help track if anything goes wrong, so it can be fixed quickly. With software for life sciences, companies can keep full records of tests and approvals, making sure every product meets the required standards consistently. This reduces mistakes and the risk of unsafe products reaching the market, and the ERP solutions support life sciences companies in keeping strong quality control and following all production rules easily and reliably.

These are the Best Pharmaceutical ERP Software for Business.

Keeping Data Safe and Accurate with ERP

When it comes to protecting high value and sensitive information, life sciences software development provide strong security features. These include detailed access controls that make sure only authorized people can see or change data, so the systems also keep secure audit trails that track every change with date and time stamps to ensure transparency.

These features help companies follow important rules and protect their data from breaches or unauthorized access. With built-in safeguards and strict security measures, life science ERP helps avoid risks of data loss, tampering, and non-compliance, keeping company and patient information safe at all times.

Reducing Costs and Growing Business with ERP

When you want to grow and scale your business, it is important to manage costs carefully and keep expenses under control. Life sciences software solutions help by tracking spending in real time and monitoring budgets to avoid overspending, and these tools make it easier to plan for future costs and allocate resources wisely.

That’s why modern ERP for pharma companies also helps reduce costs by automating routine tasks, improving efficiency, and cutting down waste plus, scalable ERP systems support business growth without needing costly changes in infrastructure. So, using ERP and life sciences software helps companies save money while expanding and staying competitive in the market.

Conclusion

Using the right ERP system is very important for life sciences companies. Choosing ERP solutions from NestorBird means you get a system made especially for pharmaceutical and life sciences companies, which helps keep everything in one place, follow strict regulations, and improve efficiency. With NestorBird, you get expert support and tools designed to meet your industry’s needs, making your business stronger and more successful.

Frequently Asked Questions

Yes, ERP systems help plan production, track materials, manage sales, and simplify marketing processes, supporting smooth market entry and better coordination across teams during product launches.

Pharmaceutical ERP has built-in tools to follow strict regulations like FDA and GxP. It keeps records secure, tracks changes, and ensures products meet quality standards to avoid costly failures.

A single ERP system connects finance, manufacturing, quality control, and more, which helps share accurate data easily, improves teamwork, and avoids delays caused by separate, disconnected software systems.