Quick Summary

The best ERP for chemical manufacturing helps businesses manage complex processes, stay compliant, and reduce costs. This blog covers top features and benefits of chemical ERP software for smooth and efficient operations.

Table Of Contents

Introduction

In the chemical manufacturing industry, businesses have to take care of and maintain numerous operations and business functions, which can consume a lot of time and resources. This is why choosing the best ERP for chemical manufacturing is important, because a tailored chemical ERP helps streamline complex production processes, making everything run more smoothly and efficiently. Chemical manufacturing faces unique challenges like managing formulas, tracking batches, and meeting strict safety rules. That’s why specialized ERP software chemical manufacturing is needed to handle these tasks. In this blog post, we will explore why the right ERP system is crucial for success in this industry.

Key Takeaways

The best ERP for chemical manufacturing simplifies complex processes.

Chemical ERP helps maintain regulatory compliance easily.

Proper ERP reduces costs by managing inventory and production well.

ERP software for chemical manufacturing improves product quality.

Choosing the right chemical ERP system supports business growth.

What Are The Challenges in Chemical Manufacturing That an ERP Solves

There are some challenges that the manufacturing process in the chemical industry faces, and a good ERP system helps solve them.

Managing various complex formulations and batch traceability: Chemical production requires careful handling of formulas and tracking batches from start to finish. A chemical manufacturing ERP or chemical ERP system makes it easier to manage these details accurately and avoid mistakes.

Ensuring proper and required regulatory compliance: The chemical industry must follow many safety and environmental rules. An ERP for chemical industry includes compliance tools that help companies meet these regulations without trouble.

Controlling costs while maintaining required efficiency: Keeping operations efficient while reducing costs is tough for manufacturers, so using the right ERP software for chemical manufacturing helps streamline processes, saving money and time.

Handling inventory complexities, issues, delays, and challenges: Chemicals often need special storage and measuring units, and thus, using an ERP for chemicals manages these inventory details properly, preventing errors and losses.

Read more on How ERP Enhances Efficiency Compliance Pharma.

Essential Features to Look for in the Best ERP for Chemical Manufacturing

Check out these features that the efficient and best suitable ERP for Chemical Manufacturing software should have to help businesses run smoothly and safely.

Advanced formula management and recipe optimization: A strong chemical ERP solution allows precise control and easy updates of chemical formulas, which also helps optimize recipes to improve product quality and reduce waste.

Batch production tracking and lot traceability: The best ERP for chemical manufacturing tracks every batch from start to finish, and also ensures full traceability and easier recall if needed.

Regulatory compliance management tools: A good chemical ERP system includes tools to manage and meet safety standards like GHS, OSHA, and EPA, helping avoid fines and risks.

Supply chain and inventory management tailored to chemicals: An effective ERP for chemical manufacturing manages chemical-specific inventory needs, including storage and material handling, while optimizing the supply chain.

Quality control and reporting functionalities: ERP software chemical manufacturing provides tools for testing product quality and generating reports, ensuring consistent standards and better decision-making.

Check out more on Pharma ERP Software for Manufacturing SMEs.

The Best ERP for Chemical Manufacturing: Top 5 Solutions

Choosing the best ERP software for chemical industry is important for optimizing operations, ensuring compliance, and improving efficiency in this industry. Here is a list of five top ERP solutions that work best in the chemical sector.

ERPNext Software: This efficient software is an open-source platform with easy-to-use modules including finance, inventory, project management, and customer service. It is customizable to fit the needs of chemical manufacturers, helping streamline processes, manage inventory, and ensure regulatory compliance effectively.

BatchMaster ERP for Chemicals: This system can help chemical manufacturers handle formulas, batch production, and compliance. It offers tools to track quality and manage supply chains, making production smoother and more organized.

Infor CloudSuite Process Manufacturing: You can choose this system because it supports chemical companies with real-time tracking, complex formulas, and environmental regulations. It also helps reduce costs by improving production and supply chain efficiency.

SAP S/4HANA for Chemicals: This ERP software provides a system for large chemical manufacturers to manage operations, supply chains, and compliance, plus offers advanced analytics to improve decision-making and productivity.

Microsoft Dynamics 365 Supply Chain Management: This ERP helps chemical manufacturers control inventory, manage recipes, and meet safety rules. It offers flexibility for companies of different sizes to improve their processes and reduce errors.

Easy Ways to Improve Data Integrity Pharma Systems

For businesses to achieve the right operational efficiency so as to grow and scale their business, they need to use the ERP software for chemical manufacturing that can streamline production workflows and reduce errors.

This type of software helps organize tasks and processes, making sure work is done correctly and quickly. It also offers strong integration capabilities with financial and other business software to bring all important operations together in one place, making management easier.

Additionally, a good chemical ERP solution provides real-time data insights, allowing managers to make better decisions based on current information. This helps improve productivity by quickly identifying problems and opportunities, leading to smoother operations and better results overall.

This is How ERP Systems Help Pharmaceutical Industries.

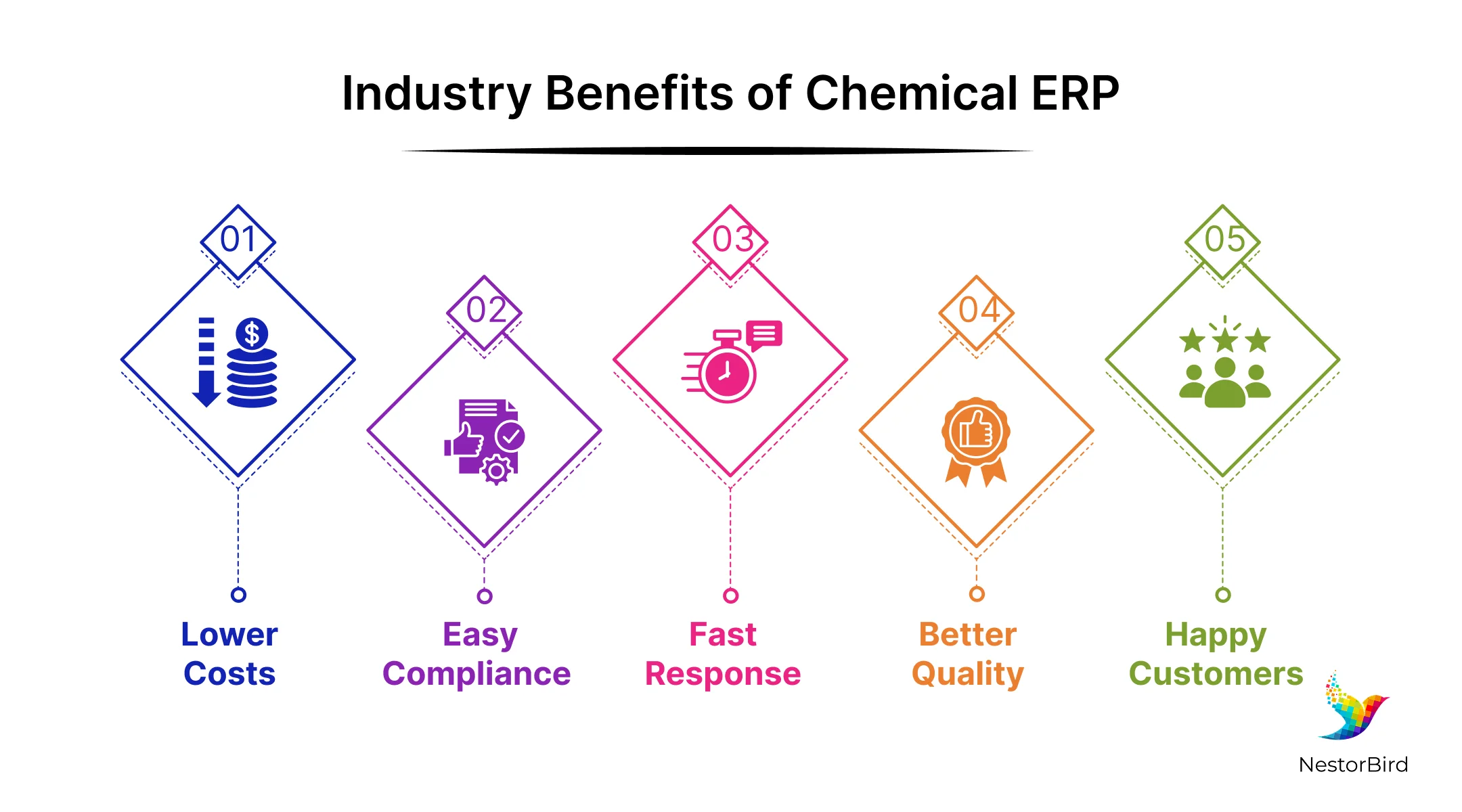

Top Industry-Specific Benefits of Implementing a Chemical ERP

There are some very industry specific benefits when businesses implement and use the right ERP for their chemical manufacturing business.

Chemical manufacturing ERP helps reduce costs by managing inventory and resources better, this way you can save money, resources, and scale your business easily.

A good chemical ERP system improves compliance with rules, lowering risks and avoiding fines, which is very important given the strict industry regulations, and guidelines.

Using an ERP for chemical manufacturing allows companies to respond quickly to market changes because the system can grow with the business, this way they do not waste any money, time or resources and are always updated on the ongoing trends in the industry.

The best ERP for chemical manufacturing helps keep product quality steady, leading to happier customers as well as recurring ones too that come back for the quality and brand value.

Learn more on ERP for Life Sciences.

Tips to Choose the Right ERP for Your Chemical Manufacturing Business

You need to consider the size of your company and how complex your manufacturing is when choosing ERP software chemical manufacturing.

It is best to pick a vendor who knows the chemical industry well and understands its specific needs, as this helps get the best chemical ERP.

Decide between cloud-based or on-premises systems based on your company’s preferences and IT capabilities when selecting ERP for chemical industry.

You should check if the chemical ERP system can grow with your business, allows customization, and offers good customer support for smooth use.

Conclusion

Choosing the right ERP for chemical manufacturing is very important to make your business work better and stay safe with regulations. Using an ERP system designed for the chemical industry can save time and money. For the best results, consider ERP solutions from NestorBird, that offer fully customizable and easy-to-use ERPNext software that fits chemical manufacturers’ needs and helps businesses grow smoothly and safely.

Frequently Asked Questions

This is because chemical production involves complex formulas, batch tracking, and strict regulations. Specialized ERP software helps manage these tasks with accuracy and ensures safety and compliance.

Look for formula management, batch tracking, inventory control, compliance tools, quality checks, and integration with financial systems to cover all chemical business needs.

Yes, ERPNext offers customizable modules for inventory, finance, project management, and supports chemical industry needs, making it a practical choice for chemical manufacturers.