Quick Summary

An ERP system for chemical industry safety helps chemical manufacturers manage safety risks and follow rules easily. It centralizes safety data, automates reporting, and improves workplace safety for better compliance and fewer accidents. This system supports smooth and safe chemical operations.

Table Of Contents

Introduction

Since the chemical industry is a very important and major industry that regularly deals with sensitive products, chemicals, and different combinations, it has to follow and comply with some very very required and important safety standards that are mainly set to protect the industry workers, the environment, and the public. Safety challenges in chemical manufacturing include handling hazardous materials, preventing accidents, and ensuring continuous compliance with regulations. That’s why technology like an ERP system for chemical industry safety plays a major role in organizing these safety processes. In this blog post, the focus will be on how an integrated ERP system, particularly for the industry safety can improve risk management and help maintain strong compliance with safety standards.

Key Takeaways

An ERP system for chemical industry safety improves risk management and helps follow safety rules.

It automates safety data and compliance reporting to avoid errors and delays.

Real-time tracking of chemicals and safety gear keeps workers and products safe.

Batch traceability and quality control ensure safe manufacturing processes.

ERP helps avoid fines and reduces accident costs by improving overall safety.

What Are The Safety Challenges in the Chemical Industry

Safety in the chemical industry mainly means dealing with sensitive, important, and potent substances that can be dangerous to people and the environment. The industry faces risks from hazardous chemicals, complex mixtures, and strict rules it must follow.

And here, without proper safety software, chemical manufacturers often struggle with managing these risks, which can lead to accidents, injuries, or legal problems. Common challenges include tracking unsafe materials, meeting safety regulations, and preventing chemical spills or fires.

That’s why using efficient, proper suitable specialized chemical industry safety software helps reduce these risks by organizing safety data, monitoring hazards, and ensuring the company stays compliant with safety laws. This makes the workplace safer for everyone involved.

This is How ERP Systems Help Pharmaceutical Industries.

How ERP System Enhances Chemical Industry Safety

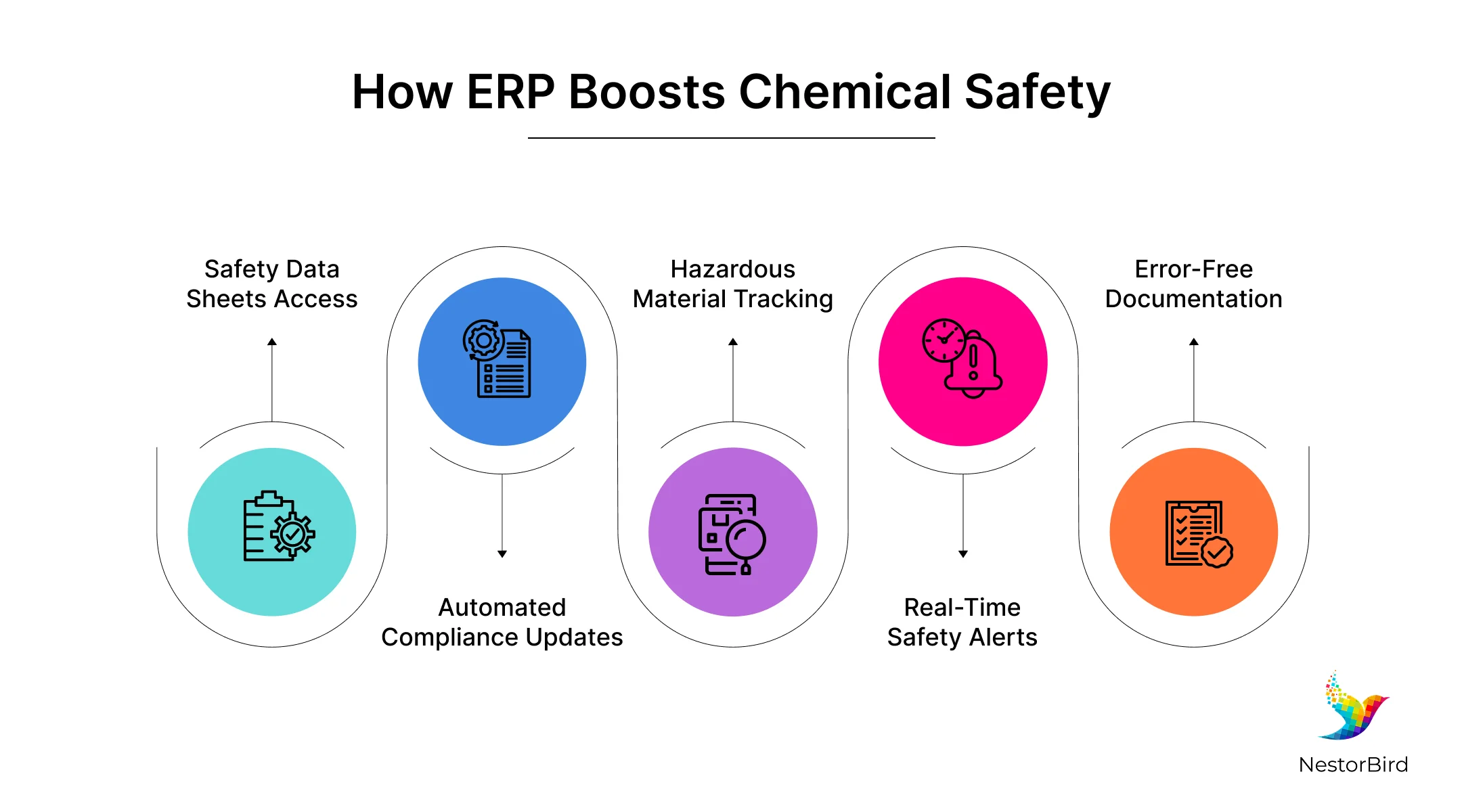

To properly and efficiently maintain the required industry safety, an ERP system for chemical industry safety integrates important safety information like Safety Data Sheets or SDS and data on hazardous materials. This integration ensures all safety details are stored in one centralized place, making it easy for workers to access the right information quickly.

The system automatically updates compliance documents, helping chemical manufacturers keep up with changing safety rules, and by organizing safety processes within an ERP, errors caused by manual handling are reduced significantly.

This efficent ERP system for the particular industry helps streamlines workflows, enforces correct handling procedures, and helps companies follow safety standards more accurately, which also helps reduce the many risks and makes the workplace safer for everyone involved.

Learn about the Top ERP Software Solutions.

Useful Features of ERP Systems Driving Safety Improvements

There are some important and useful features that the best ERP systems offer to improve safety in chemical manufacturing:

The safety data sheet management and compliance monitoring help store, update, and share all safety documents needed for standards like OSHA, EPA, ISO, and DOT, and this ensures that chemical risks are always properly recorded and handled.

Features like incident reporting and emergency response planning within a chemical ERP solution make it easy to record accidents and prepare action steps for emergencies. This helps teams respond faster and follow the right process during any unsafe event.

The proper and efficient real-time inventory tracking of hazardous materials and safety gear with ERP software chemical manufacturers keeps an up-to-date record of all risky materials and safety tools. It helps prevent misuse and allows quick access when needed.

Since it is important to ensure quality assurance and batch traceability, ensure every product follows safety standards. The ERP system tracks products from start to finish, making it easier to find and fix any issues that could affect safety.

Another important feature which is environmental and workplace safety compliance, using ERP risk management chemical manufacturing means rules for safe workspaces and pollution control are always followed. The ERP system supports regular safety checks, audits, and documentation, making compliance easier.

Let us understand Why Data Integrity Is Key to Pharmaceutical Compliance.

The Many Benefits of Using ERP Risk Management for Chemical Manufacturing Safety

There are many advantages and benefits of choosing to implement the right ERP solution for the chemical industry, especially to maintain proper manufacturing safety.

An ERP for chemical industry safety uses built-in data analytics to spot safety risks early. This helps managers take action before problems happen, making the workplace safer for everyone.

The software makes compliance easy by automatically preparing and storing all necessary reports. It helps chemical manufacturers be ready for audits and follow safety regulations without missing any rules.

Because of useful real-time monitoring tools in ERP software chemical manufacturers, the manufacturers can check for unsafe conditions and provide warnings, which also reduces accidents and keeps workers protected at all times.

ERP risk management chemical manufacturing helps avoid fines and penalties by ensuring strict safety compliance. It also saves money by preventing accident-related costs and improving overall safety.

Here, the system tracks every batch and material movement, making it easy to spot safety issues or defects. This leads to better quality products and stronger safety records for chemical manufacturers.

These are the Best ERP for Chemical Manufacturing.

Know More About Future Trends: EHS and ERP System Integration in Chemical Industry Safety

The chemical industry should also keep track and stay updated on some of the future trends that can easily change the way the system performs its daily operations, and during other stages, such as the growth and scaling phases.

The efficient modern ERP software for chemical industry systems now includes EHS modules that help companies manage safety risks and meet compliance rules more easily.

IoT technology is becoming important because it provides real-time safety monitoring, with which the sensors connected to ERP solutions send instant data about equipment, materials, and working conditions, helping stop problems early.

Another big trend is predictive safety management, where systems use collected data to predict and stop accidents before they happen.

Also, remember that here, sustainability is also an important focus point for this industry, and new ERP solutions help chemical manufacturers can greatly help reduce waste, save energy, and follow environmental laws as part of daily operations.

Final Note

For the chemical manufacturing industry, choosing a good ERP system can be beneficial and important considering the required safety standards that it needs to follow and comply to. Businesses in this industry should make sure to only choose the right ERP solution, that can follow government rules, reduce accidents, and keep everything updated. Using ERP solutions from NestorBird is recommended because the systems are easy to use, support strict safety and compliance needs, and are designed for chemical manufacturers. With NestorBird, companies can track batches, follow safety rules, and stay ready for future business growth.

Frequently Asked Questions

The efficient ERP systems organize safety data, automate compliance checks, track materials, and provide instant access to safety documents, which also helps avoid mistakes and keeps the workplace safe.

The ERP software generates compliance reports, monitors rules like OSHA/EPA, and keeps all your safety data in one place, making audits simpler and avoiding legal fines for missed standards by your industry.

Yes, ERP solutions help provide warnings, track incidents, and help create emergency plans. These features mean accidents can be identified and prevented early, keeping workers and products safe.