Quick Summary

Business intelligence pharma helps pharmaceutical companies use data to improve manufacturing, control quality, and meet regulations. It supports faster decisions and smoother operations, making pharma businesses more productive and competitive.

Table Of Contents

Introduction

In the pharmaceutical industry, manufacturers and organizations need reliable ways to use data for better choices and improving their daily processes. Business intelligence pharma helps companies gather, analyze, and understand large amounts of information from different sources. As the industry faces strong competition and changing regulations, using business intelligence has become necessary to work more efficiently and make accurate decisions. In this blog post, readers will see why business intelligence pharma is now essential for achieving strong manufacturing and operational results.

Key Takeaways

Business intelligence pharma helps improve drug production speed and quality.

It supports better compliance by automating reporting and monitoring regulations.

BI tools increase efficiency through real-time data and process monitoring.

Using BI helps identify risks early and improve decision-making accuracy.

Pharma companies can boost sales and manage supply better with BI insights.

What is Business Intelligence in Pharma Manufacturing?

Now in current times, for pharma businesses to make the most out of their data, business intelligence in pharma manufacturing is important. Business intelligence in pharma manufacturing means using tools and software to collect, combine, and analyze information from different parts of the company. By adding advanced analytics and artificial intelligence, drug makers can find patterns and solve problems much faster.

Here, business intelligence pharmaceutical focuses on making decisions for things like research, production, and sales using real-time data. On the other hand, pharmaceutical business intelligence is a wider practice. It includes not just factory work but also looks at the whole company’s strategies, market research, and competition. Both are needed, but each has its special use.

This is How ERP Systems Help Pharmaceutical Industries.

Some Important Challenges Faced by Pharma Manufacturers

There are many small or big challenges that the industry faces, especially in pharma manufacturing, where smart data use is needed.

Data silos and integration issues make it hard to gain insights: Information here is often separated or hard to combine, making it difficult to see the full picture and take action, so using business intelligence pharmaceutical tools helps join up these data sources.

Compliance reporting and regulatory pressure: Pharma companies must follow strict laws and rules, and reporting all these needed details on time is hard. Using business intelligence in pharma manufacturing makes this task quicker and reduces mistakes.

Need for predictive tools for quality control: Business intelligence in pharma makes checks simple, where keeping products safe and good quality is a must. Here, predictive tools and smart systems give early warnings when issues start.

Rising R&D costs and patent issues: Research is expensive and patents often expire fast, which then pushes companies to look for new methods and save money. Smart pharmaceutical business intelligence solutions can guide teams on smarter spending.

Supply chain disruptions: The unexpected delays with raw materials can slow production, and global events or transport problems increase risks. Using business intelligence pharma improves scheduling and makes sure work does not stop.

Learn more about other Pharma ERP Challenges Opportunities Tips.

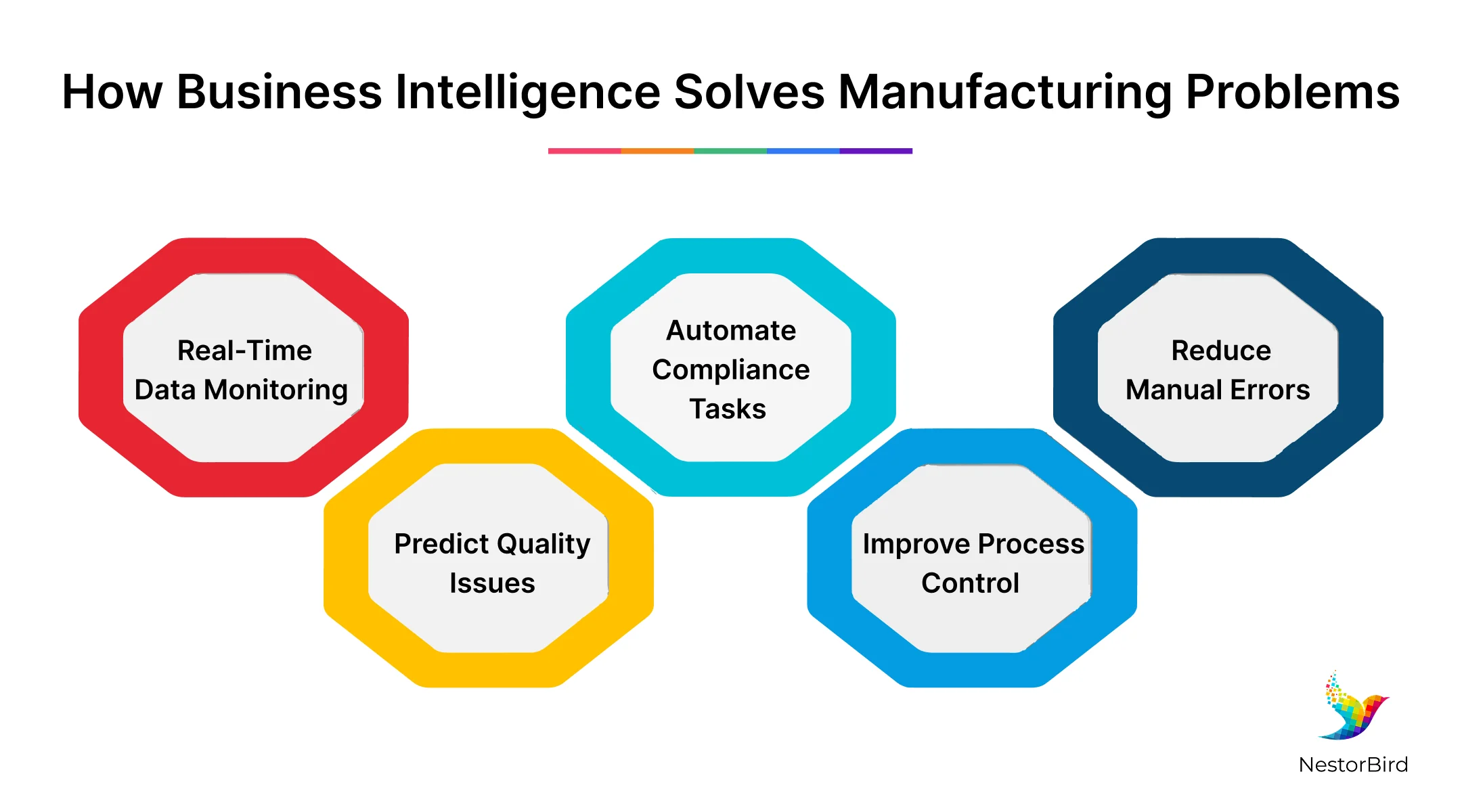

How Business Intelligence Solves Manufacturing Problems

The manufacturing problems in the pharma industry can mean that businesses have to face delays, mistakes, and extra costs. Using business intelligence in pharma helps companies watch data in real time from R&D, clinical trials, and batch production. This way, teams quickly spot errors and finish work faster with fewer delays.

In this industry, risk assessment also improves with smart systems, where business intelligence pharmaceutical tools help track consistency, quality, and safety during manufacturing. This way, the teams get warnings before problems get worse, so actions are taken in time.

Using business intelligence in pharma manufacturing also makes compliance reporting easier, and then reports and data can be made quickly and correctly with less manual effort, which lowers the chances of human error or missed details.

Choose from the Best Pharmaceutical ERP Software for Business.

How Business Intelligence Differs From Other Data Tools in Pharma

Business intelligence in pharmaceutical focuses on collecting, organizing, and analyzing data specifically to help pharma companies make better decisions about manufacturing, research, and sales. It combines data from many sources and provides clear reports and insights that help teams act faster and smarter.

Other data tools might only look at one part of the process or give limited information. Since this business intelligence is broader and covers multiple areas like clinical trials, supply chains, and market trends, it is more helpful for overall business planning. It also uses advanced analytics and AI to predict trends and risks, which other basic tools may not offer. This makes business intelligence essential for staying competitive in the pharma industry.

Useful Tips To Implement Business Intelligence in the Pharma Industry Effectively

Define clear goals before starting: Decide what your pharma company wants to improve, like reducing costs or speeding up production, so here, having clear goals helps focus business intelligence pharma efforts on what matters most and measure success better.

Build a cross-functional team: Include members from IT, manufacturing, quality, and management. This helps ensure that business intelligence pharmaceutical tools fit everyone’s needs and that data from multiple areas is used effectively.

Choose the right business intelligence tools that are easy to use and secure: A good ERP System Pharmaceutical industry should support pharma-specific needs like compliance reporting and data integration, which makes the process smoother and more reliable.

Clean and integrate data from different sources: Unrelated, fragmented, and incorrect data can cause wrong decisions, so combining data sets carefully ensures that pharmaceutical business intelligence delivers accurate insights.

Provide training and support to staff using BI systems: This helps increase adoption and reduces resistance, and teams should understand how to use business intelligence in pharma manufacturing for daily tasks and decision-making.

Impact on Operational Efficiency and Decision-Making

When businesses implement the right software for their business, they can see drastic improvements and changes in their operations. Pharmaceutical business intelligence helps companies use data to increase productivity by streamlining processes and reducing downtime. It allows teams to quickly identify issues and fix them, improving work speed and quality.

With these tools and features, the dashboards and data visualization tools provide clear, real-time views of key numbers. Pharma & medtech business intelligence tools offer instant feedback, helping managers make smart decisions faster, and these visuals reduce the need to dig through raw data and keep all teams informed on the latest status and risks.

Final Note

For companies wanting to improve manufacturing, compliance, and decision-making in the pharmaceutical industry, using business intelligence pharma can be a great advantage. ERP solutions from NestorBird are a practical choice, as NestorBird’s ERP software is built specially for the pharmaceutical industry to handle production, quality control, inventory, and regulations in one place. Their easy-to-use system helps businesses stay compliant and operate more efficiently, making it a smart investment for pharma manufacturers aiming for growth and safety.

Frequently Asked Questions

Data comes from clinical trials, production lines, sales, supply chains, quality checks, and regulatory reports. Combining these helps pharma companies get clear insights for operations and compliance.

Yes, it automates compliance reporting, tracks quality standards in real time, and reduces human errors, helping pharmaceutical companies meet strict legal and safety requirements more easily.

AI improves data analysis speed and prediction accuracy. It helps identify quality issues, optimize clinical trials, and forecast market trends for smarter decision-making in pharmaceutical production.