Quick Summary

Pharma inventory management software helps pharmaceutical companies manage stock efficiently. It reduces waste, improves accuracy, ensures regulatory compliance, and supports smooth production. This software is a key tool for any pharma manufacturing business looking to optimize operations and control costs.

Table Of Contents

Introduction

For any pharma business, to maintain, manage, and efficiently control inventory is very important, but also can be challenging. Thus, managing raw materials, work-in-progress, and finished goods while avoiding errors can be difficult. Without proper tracking, companies face risks like expired stock, overstocking, and delays in production, and these problems can affect medicine quality and increase costs. In this blog post, let us see why using a pharma inventory management software is important for your business, as this software helps businesses keep accurate records, reduce waste, and improve overall efficiency in pharmaceutical inventory management. It is a key tool for smooth operations in pharma manufacturing.

Key Takeaways

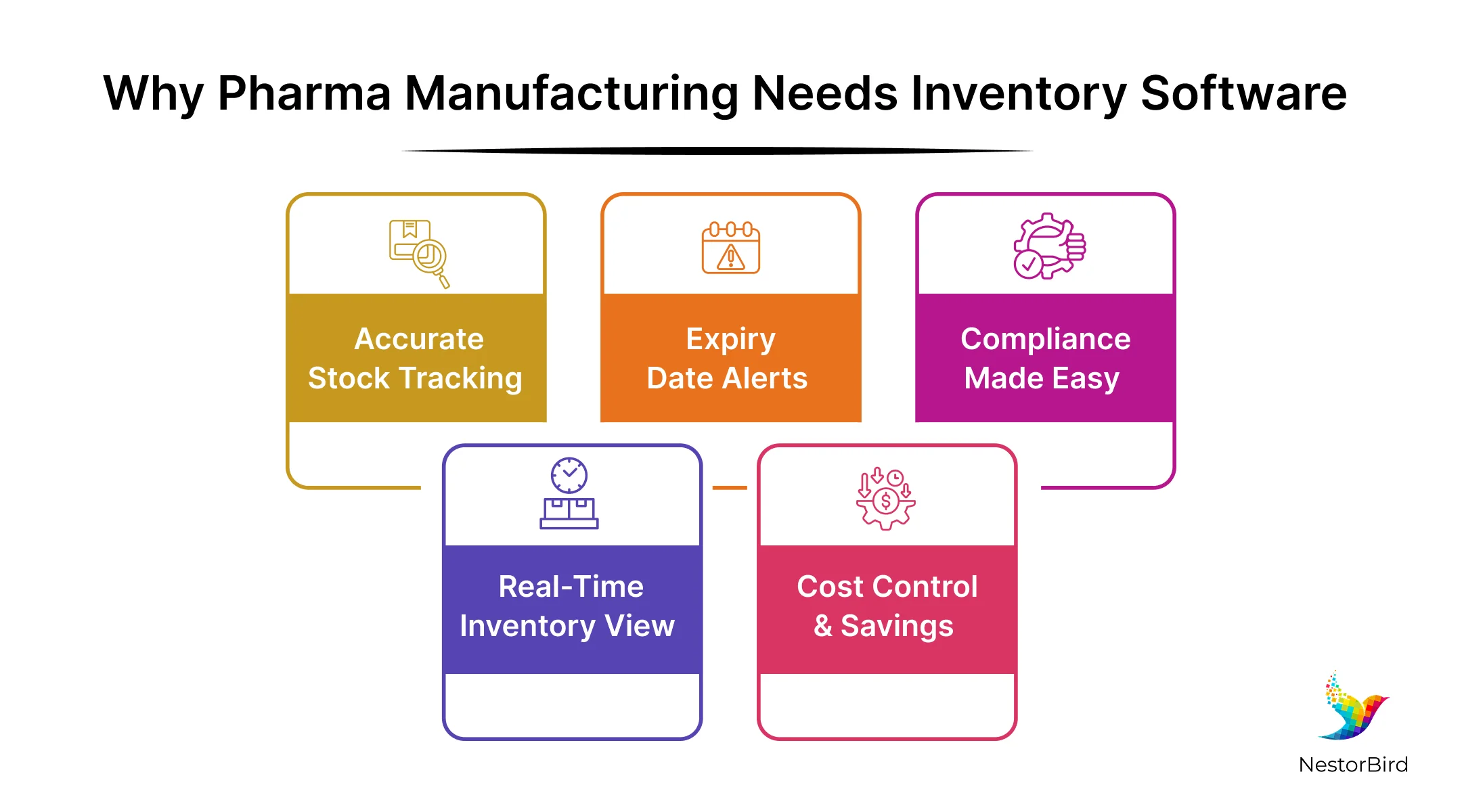

Pharma inventory management software helps track and control stock.

It reduces waste by managing expiry dates and batch numbers.

The software ensures compliance with industry regulations.

Real-time inventory visibility improves production efficiency.

It helps control costs by preventing overstocking and stockouts.

Need 1: Effective Pharmaceutical Stock Management to Reduce Wastage

Keeping a tab on your stocks across various batches, different types, and specific expiry dates is very important in pharma manufacturing, and here a good pharmaceutical stock management helps prevent waste caused by expired or extra materials that are not needed. A strong pharmaceutical inventory management system tracks expiry dates and batch numbers clearly, so you know which stock to use first.

This helps avoid using outdated materials or losing products because they passed their expiry. A reliable pharmaceutical inventory solution reduces dead stock by making sure medicines and materials are used on time. This way, companies can save money and keep the production process smooth and efficient, preventing losses from wasted inventory.

These are the Top ERP Software Solutions.

Need 2: Compliance with Regulatory Requirements and Quality Standards

Since the pharma industry is highly and heavily regulated, as they need to maintain strict standards when it comes to their potent, important, and sensitive products, pharmaceutical inventory management systems play a very important role here. These systems help maintain detailed audit trails to meet rules set by FDA, GMP, and other regulators.

Inventory management software in pharma manufacturing helps with accurate documentation, easy reporting, and full traceability of products and materials, which also makes it simpler for companies to prove they follow the rules. Thats why using good pharma manufacturing software reduces the risk of mistakes and helps avoid costly fines and penalties, ensuring the company stays compliant and their products are safe and reliable for use.

Check out the ERP for Pharmaceuticals Challenges and Benefits.

Need 3: Real-Time Inventory Visibility for Production Efficiency

To manage the pharma business efficiently, and so as to manage and maintain profits, having instant and clear visibility of inventory is very important. Pharma inventory management software provides real-time updates on stock levels, helping companies know exactly what materials they have at any time, and this helps reduce production downtime by making sure raw materials and intermediates are available when needed.

When combined with Pharmaceutical inventory solution modules, the software can also integrate smoothly with Pharma ERP systems, as this integration allows all departments to work together without delays or errors, ensuring smooth workflows and better coordination, which is to improve production efficiency and lower the chances of costly bottlenecks.

Need 4: Better & Improved Forecasting and Demand Planning Capabilities

To better understand your business’s needs and avoid running out of important materials, inventory management software in pharma manufacturing uses data analytics to predict changes in demand. This helps companies plan for seasonal ups and downs or shifts caused by market trends. By knowing what to expect, businesses can adjust their inventory levels accordingly.

And it is this feature that is very helpful in pharmaceutical inventory management because it allows better planning for buying and making products. When procurement and production schedules are optimized, companies can avoid overstock or shortages. This helps save money and keeps the production line running smoothly without interruptions. To improve how pharma companies manage their stock efficiently.

This is How ERP Systems Help Pharmaceutical Industries.

Need 5: Highly Streamlined Inventory Processes to Improve Your Productivity

To improve your productivity and make sure that your business runs smoothly, using pharma manufacturing software to automate routine inventory tasks is very helpful. Tasks like stock counts and reconciliation can be done automatically, saving time and effort. When a pharmaceutical inventory solution is in place, there is less chance of manual errors because less human intervention is needed.

This again also helps keep accurate records and reduces mistakes, and as a result, the overall productivity of the workforce improves. Companies operating at a larger scale with pharmaceutical inventory management find these benefits especially important because they handle more stock and complex processes, to help pharma businesses work faster and more efficiently.

This is the Best Pharmaceutical ERP Software for Business.

Need 6: Cost Control and Efficient Resource Utilization

Businesses are always working towards saving and controlling unnecessary expense, so using pharma inventory management software helps a lot in this area. This software prevents having too much inventory or running out of important materials, which helps optimize working capital. And this way, using accurate pharmaceutical stock management makes sure companies buy only what they need.

This reduces procurement costs and cuts down on storage expenses by avoiding excess stock. Technology also plays a key role by enabling just-in-time inventory replenishment. This means materials arrive exactly when needed, not too early or too late and, using these tools helps pharma companies use their resources efficiently and keep their costs under control.

Need 7: Improved Accuracy and Reduced Human Errors in Inventory Management

If pharma businesses do manual inventory tracking it can often lead to mistakes that can affect production and compliance, so using a pharma inventory management software greatly improves accuracy by automating data entry and stock updates. This reduces the chance of human errors like incorrect counts or misplaced items.

A pharmaceutical inventory solution ensures that all inventory information is updated in real-time and is easy to access, which helps staff make better decisions based on correct data. And then by minimizing errors, companies avoid production delays and costly quality issues. Improved accuracy also supports smoother operations in large-scale pharmaceutical inventory management environments and helps maintain trust with regulators and customers.

End Note

So, using a good pharma inventory management software is very important for pharma companies, as it helps manage stocks, reduce waste, follow rules, and keep production running smoothly. Without proper tools, managing pharmaceutical inventory can be hard and costly, and that is why companies need reliable pharmaceutical inventory solutions. NestorBird offers strong ERP solutions made for pharma businesses, helping them manage inventory and operations efficiently. Choosing NestorBird’s ERP can make your pharma inventory easier to control and improve overall productivity, which is a smart choice for growing pharma companies.

Frequently Asked Questions

By tracking expiry dates and batch numbers, it ensures timely use of medicines and raw materials, helping prevent expired stock and reducing losses from overstocking.

It automates stock counts, reconciliation, alerts for low stock, and expiry tracking, reducing manual errors and saving time.

Yes, it scales to company size, improving accuracy, saving time, and supporting compliance whether for small or large pharmaceutical manufacturers.