Quick Summary

This blog shares the Top ERP Software Solutions for retail businesses. You will learn how these systems help manage sales, stock, and customers in one place. Find out which Top ERP Software Solutions can make your shop work better and help your business grow faster.

Table Of Contents

Introduction

If you are always hearing about the many benefits of ERP systems and software but thinking if it is really worth it, and if it will suit your business, you are not alone. Many manufacturers wonder if investing in manufacturing ERP software will actually solve their daily problems or just add more work. In this blog post, we will explain what manufacturing ERP software can do, the real benefits it brings, and how to decide if it is the right choice for your company.

Key Takeaways

Manufacturing ERP software brings all your business data into one system.

It helps reduce mistakes and saves time in daily work.

ERP systems make it easier to manage growth and complex processes.

You get real-time updates on inventory, production, and finances.

Choosing the right ERP software can improve your business results.

Is Your Manufacturing Business Outgrowing Spreadsheets?

If you are still using spreadsheets to manage your manufacturing business, you might notice some problems as your company grows, as nowadays spreadsheets often have mistakes because everything is entered by hand, and it takes a lot of time to update them. They do not show real-time information, so you might be looking at old data when making decisions. When your business gets bigger, spreadsheets become slow, hard to use, and it is easy to lose track of the latest version, which in turn can lead to confusion, delays, and even security risks. Similarly, find out about ERP for Retail Business.

That’s why manufacturing ERP systems help solve these problems by giving you one place to manage all your data, where they update information automatically, help your team work together, and make it easy to follow rules and keep up with changes as you grow. With manufacturing ERP software, your business can handle more orders, more products, and more customers without the stress and mistakes that come with spreadsheets.

What Does Manufacturing ERP Software Actually Do?

Manufacturing ERP software helps you run your business by bringing all your main tasks into one system, and handles planning, buying materials, tracking inventory, managing orders, and keeping an eye on your money, all in one place. With the use of the right ERP software for manufacturing, you can see what is happening on your shop floor, know how much stock you have, and check your finances at any time, which means you do not have to use different programs for each job, which saves time and reduces mistakes.

Manufacturing ERP software systems also helps you plan your production, follow quality standards, and work better with your suppliers, as it efficiently connects your shop floor, inventory, and finance teams, so everyone has the same information and can work together easily. This makes your business more organized and helps you make better decisions every day.

Here is How ERP Can Fit into Retail Business.

When Is Manufacturing ERP Software the Right Move?

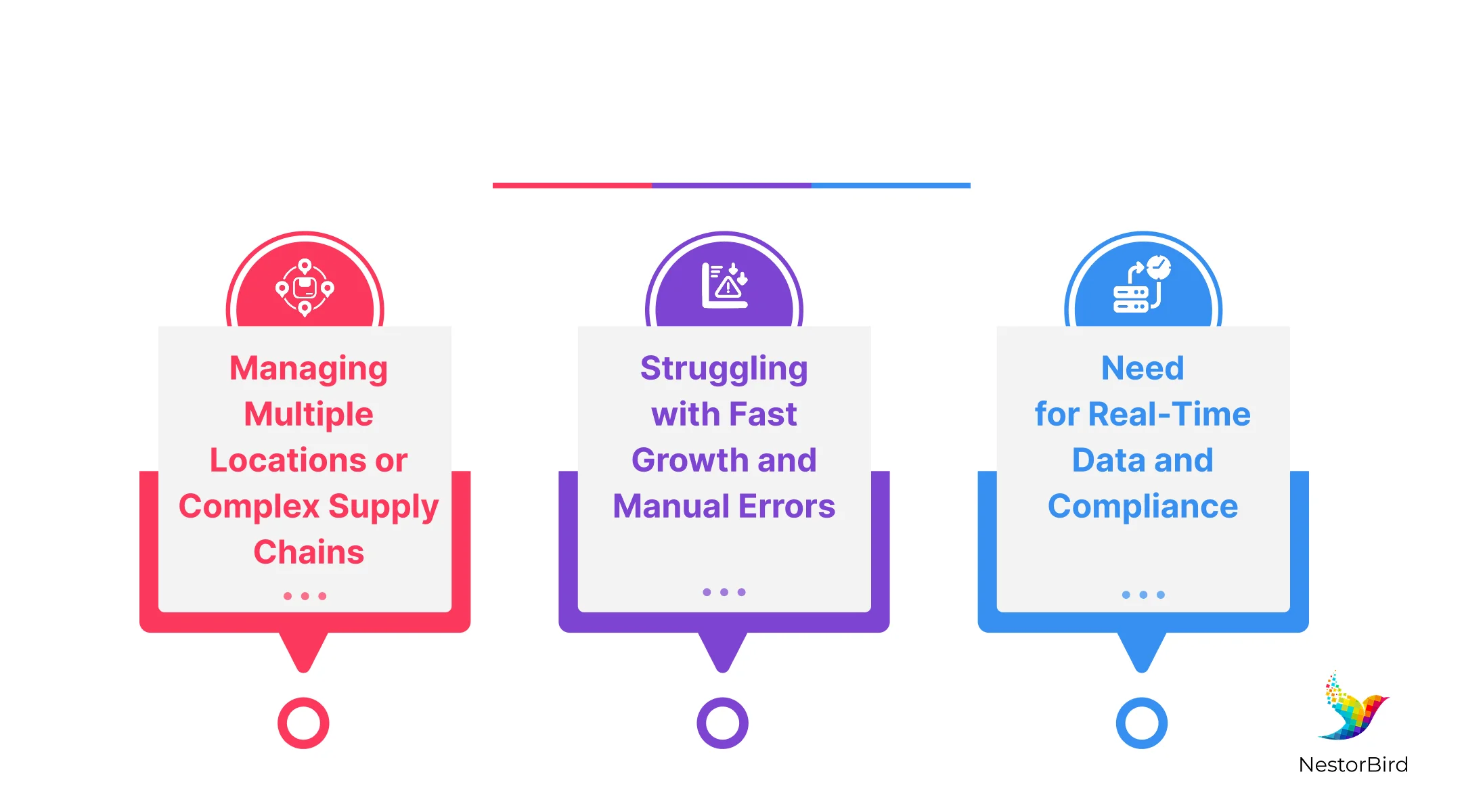

Let us look at some of the business scenarios that demand a manufacturing ERP solution to help you grow and scale it properly and efficiently.

When You Need a Manufacturing ERP Solution

You have more than one factory or warehouse and need to manage them together.

Your supply chain is complex, with many suppliers and lots of moving parts.

Your business is growing fast, and it’s hard to keep up with orders, stock, and deliveries.

You need to follow strict rules or industry standards for quality and reporting.

Your current tools can’t give you real-time updates or clear reports.

You spend too much time fixing mistakes or searching for information.

Here are the Benefits of ERP Software for Non-Profit.

When Basic Manufacturing Software Might Be Enough

You have a small business with simple processes.

You do not have many products or locations.

You don’t need to follow many rules or handle complex supply chains.

Your current system works well, and you do not face delays or mistakes often.

Also, remember, the manufacturing ERP systems are best when your business is growing or getting more complex, like for small, simple setups, basic software may be enough.

Their ROI and Real-World Impact: Is It Worth the Investment?

Yes, in the real world, manufacturing ERP software can bring real benefits to your business, and most companies see better productivity, fewer mistakes, and lower costs after using manufacturing ERP systems. For example, 78% of businesses report higher productivity, and 62% say their costs went down after using manufacturing software ERP, and many companies also find it easier to manage inventory and work with suppliers, which saves time and money.

Some of the real results show that manufacturers often get back their investment in ERP within 2 to 3 years, and some companies have seen sales grow, costs drop, and fewer errors in orders and stock. This actually shows that the right ERP can make a big difference for many manufacturing businesses.

How to Choose the Right Manufacturing ERP System for Your Needs

Now that we know why you need ERP manufacturing systems, let us understand how you can choose one that is right for your specific business. Here is a checklist with all the must-have features and integration capabilities.

Checklist of the must have features for your business

You can make a list of what your business needs from manufacturing ERP software. For this, you can get input from your team and check if the software can handle your production type, inventory, supply chain, and reporting needs.

Always best to look for features in Retail Business ERP Solution, like real-time inventory tracking, production planning, order management, and easy reporting.

You should make sure the manufacturing software ERP system can connect with your current tools and systems, like accounting or CRM software.

The software should be easy to use, flexible, and able to grow with your business.

Always check if the ERP can be used on mobile devices and supports new technology like AI or IoT.

Also, pick a system that offers good support, regular updates, and is trusted by other manufacturers.

Tips for evaluating manufacturing ERP systems

You should compare different manufacturing software systems using your list of needs as a guide.

It is best to ask for a demo to see how the software works in real life.

You should make sure the vendor understands your industry and has experience with businesses like yours.

Try to check the total cost, including setup, training, and support.

It is best that you avoid choosing a system just because it is popular, and just focus on what fits your business best.

Try to involve your team in the decision to make sure everyone’s needs are met.

Conclusion

We understand that choosing manufacturing ERP software is a big decision for any business, it can help you save time, reduce mistakes, and make your work more organized. If your business is growing or getting more complex, manufacturing ERP systems can make a real difference. This way, you can decide if manufacturing ERP software is the right choice for you and your future plans.

Frequently Asked Questions

If you face slow updates, errors, or trouble tracking orders as your business grows, it is time to consider manufacturing ERP systems for better control and real-time data.

The setup time here depends on your business size and needs. Most companies can expect a few months for planning, training, and moving data into the new system.

You can expect faster work, fewer mistakes, better inventory control, and easier reporting. Many businesses see cost savings and improved productivity within the first year.