Quick Summary

This blog explains why ERP software for chemical manufacturers is needed today. It covers challenges, important features, and new trends in ERP that help chemical companies improve safety, manage formulas, and control costs for better growth.

Table Of Contents

Introduction

Every industry needs new changes whether it comes to technology, implementing new techniques, or improving processes to stay competitive. The chemical manufacturing industry faces some specific and unique challenges such as strict safety regulations, complex production processes, and managing hazardous materials. These issues make it hard to maintain efficiency and compliance using traditional methods. In this blog post, we will explore the need for ERP software for chemical manufacturers and how next-generation chemical ERP solutions help overcome these problems by improving operations, safety, and regulatory control.

Key Takeaways

ERP software helps chemical manufacturers manage production, inventory, and compliance in one system.

It improves cost control by reducing waste and optimizing raw material use.

Real-time tracking of batches and inventory ensures product quality and safety.

Automated compliance features help avoid fines and meet regulations easily.

Cloud and AI-enabled ERP prepare businesses for future growth and faster decision-making.

The Various Challenges in Chemical Manufacturing Operations

Since the chemical industry is different, it has its own set of challenges that need the proper and required attention and resolving so that businesses can grow and scale.

Efficient and Better Cost Control: Managing costs is hard because raw material prices can change a lot. Also, it’s difficult to predict how much to produce. This means businesses might waste money on materials or have too much inventory, which sits on shelves and ties up cash.

Following Required Regulatory Compliance: Chemical companies must follow many strict laws. These rules are about safety, how to handle dangerous materials, and protecting the environment. So, keeping up with these rules and creating all the necessary paperwork is time-consuming and can lead to big fines if something is missed.

Dealing with Inventory Complexity: Chemicals often have unique storage needs, like a short shelf life or specific temperature requirements. Since in this industry, many materials are hazardous, tracking these items, especially when they come in different units, like gallons and pounds, makes managing inventory very complex and prone to errors.

Check out the Top ERP Software Solutions.

Maintaining Proper Product Quality: Ensuring every batch of a chemical product is the same is a big challenge, as even small changes in raw materials or the manufacturing process can affect the final product. So here, maintaining consistent quality is really important for customer satisfaction and avoiding recalls.

High Production Agility: It’s hard for chemical companies to quickly adjust to new market demands, which is mainly due to the changing production lines to make a new product or scaling up a popular one takes a lot of time. And it is this lack of flexibility that can cause them to miss out on new business opportunities.

Outdated Systems Can Hinder Growth: If businesses use old software and separate systems they will not work together well. Information is often stuck in different places, making it hard to get a full picture of the business, and this leads to bad decisions, missed deadlines, and an inability to grow because processes are manual and slow.

What is Next-Generation ERP for Chemical Manufacturing?

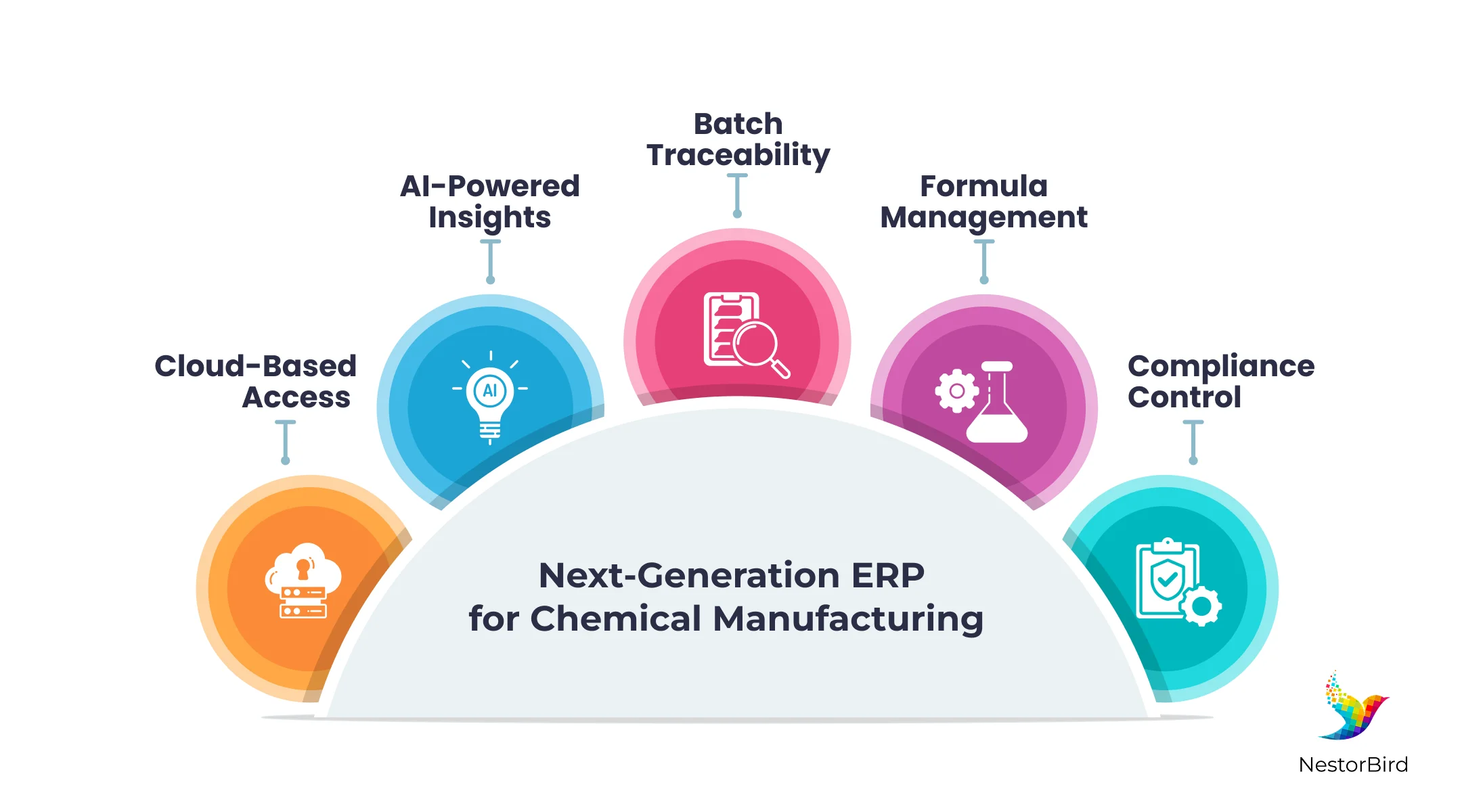

Let us understand what exactly is next-generation ERP that is suitable for the chemical manufacturing industry, and why it matters. The next-generation ERP software chemical manufacturers rely on is modern software and feature sets that are mainly designed to meet specific chemical industry needs. It is often cloud-enabled, allowing easy access from anywhere, plus it uses AI and real-time analytics to improve decision-making and productivity.

This advanced specialty chemical manufacturing software offers features like precise formula management, batch tracking, and strict compliance control. It helps manufacturers handle complex formulations, monitor each batch carefully, and meet safety regulations easily, and this type of chemical ERP solution ensures operations run smoothly while keeping quality high and costs low. It prepares chemical manufacturers for current challenges and future growth in a fast-changing market.

This is How ERP Systems Help Pharmaceutical Industries.

Essential Next-Generation Features of ERP Software for Chemical Manufacturers

Advanced batch and lot traceability: This feature lets you track every single item from the start to the finish. If there’s ever a problem with a product, you can quickly trace it back to the exact batch of raw materials used, which is also useful for fast and efficient product recalls.

Real-time inventory tracking: The software in ERP for chemical industry tracks your inventory in real time, plus it monitors specific details that matter for chemicals, such as temperature, purity, and expiration dates. This helps prevent spoilage, ensures product quality, and avoids issues with materials that are no longer effective.

Formula and recipe management: This feature is built specifically for chemical processes, which helps you manage and adjust your product formulas accurately. You can easily keep track of different versions and scales, making it simple to create consistent products every time, which is key for quality control.

Learn more about ERP for Life Sciences.

Compliance modules: The system has built-in tools to help you follow all the strict rules, as this is necessary for this particular industry. It can automatically create safety data sheets, and then make sure labels are correct, to prepare all the information you need for an audit. This also helps you save a lot of time and avoid costly fines.

Analytics dashboards: These dashboards on the chemical ERP solution show you important information in real time, so that you can use this data to predict future needs and spot potential quality issues before they happen. This way you can plan better and maintain high product standards that are usually required for this industry.

Future Trends in ERP for Specialty Chemical Manufacturing

These trends or features in next-generation ERP for chemicals software can greatly help your business grow and scale in an efficient way over time. These tools designed for the future, making special chemicals more efficient, safer, and environmentally friendly while helping businesses grow and adapt.

AI and machine learning help chemical manufacturers plan production smarter and optimize yields by analyzing data and predicting outcomes when they implement ERP software for chemical industry.

Cloud ERP software for specialty chemical manufacturers allows remote access to systems from anywhere, making it easier to manage operations and scale as the business grows.

As more and more ERP systems focus on sustainability, they do it by tracking the full lifecycle impact of chemicals, helping companies reduce waste and meet environmental goals.

Also check out these Pharma ERP Challenges Opportunities Tips.

Final Note

Using ERP software is very important for chemical manufacturers to manage their business well and stay competitive. Next-generation ERP for chemical manufacturers helps improve efficiency, control costs, maintain quality, and meet safety regulations easily, which makes operations smoother and safer. NestorBird offers ERP solutions designed specifically for manufacturing industries, including chemical manufacturing. Our ERP systems are easy to use, customizable, and provide real-time data access, and also offer expert support 24/7 to help businesses implement and run their ERP smoothly.

Frequently Asked Questions

ERP tracks safety data, labeling, and audit documents automatically, ensuring chemical companies follow all government rules and reduce the risk of penalties.

Yes, cloud ERP provides remote access, easier updates, and scalability, making it ideal for growing chemical businesses.

Batch traceability tracks every batch from raw materials to finished goods. It helps in quick recalls and ensures product safety and quality.