Quick Summary

Process ERP software is an important tool for pharmaceutical manufacturers. It automates batch management, controls inventory, and ensures compliance with all required regulations. Process ERP software brings better efficiency and helps meet industry standards, making it a valuable solution for pharma businesses wanting to improve quality, accuracy, and compliance in their daily operations.

Table Of Contents

Introduction

The pharma industry has always had to follow the many important and required compliances and regulations, and now with modern systems and stricter rules, every step of medicine production must meet high standards for safety and quality. Companies must keep track of all manufacturing details, use proper controls, and meet guidelines from health authorities. In this blog post, we will see why there is a bigger need for efficiency, better record-keeping, and full traceability at every stage, with process ERP software that helps protect patients, increase trust, and make sure every product meets the latest industry rules.

Key Takeaways

Process ERP software helps pharmaceutical manufacturers maintain strict compliance with industry rules, reducing risks and ensuring safer product quality.

ERP systems automate production tasks like batch tracking and formula management, lowering errors and saving time.

Real-time inventory and supply chain visibility through ERP avoid shortages and product waste.

Pharma ERP improves data handling and audit readiness, making regulatory inspections faster and simpler.

These solutions support better resource use and business growth while keeping all pharma operations connected and controlled.

What is Process ERP Software & Its Relevance to the Pharmaceutical Sector

In the pharmaceutical sector, when businesses use and implement the right process ERP software, it can greatly improve how they work every day. This software is built for the unique and strict demands of medicine manufacturing. It helps companies plan, make, and check their products step by step.

And unlike when using the general ERP tools, pharmaceutical ERP software lets pharma companies carefully manage formulas, keep full batch records, and follow every material across the supply chain. With these features, it supports all the strict rules for making medicine and keeps all quality checks in order.

A modern ERP system pharmaceutical industry connects different departments, like production, quality, inventory, and sales, all on one platform, as this setup makes it easier to track information, share data, and control every part of the process in real time. It helps teams work together and ensures nothing is missed, so every step is fully clear and safe.

These are the ERP for Pharmaceuticals Challenges and Benefits.

Important Compliance Features: Meeting Pharmaceutical Industry Requirements

Required Compliance Guidelines: The pharma industry is required to comply with and follow certain important guidelines for the overall safety and quality of medicines. These include rules like FDA, EMA, GMP, and TGA, which set standards for how drugs must be made, checked, and tracked. pharmaceutical industry compliance and process ERP software help companies follow these laws closely.

Document Control and Record Keeping: A strong pharma ERP software lets businesses store all documents safely, track changes, and maintain clear records of each batch. The ERP system allows secure electronic signatures, keeps every transaction visible, and creates complete audit trails for easy review as per the rules.

Regulation Change Management: With new rules coming in often, an ERP system pharmaceutical industry can quickly adjust processes through validation and testing tools. The software helps update workflows and ensure secure data handling, so pharma manufacturers always stay in line with the latest regulations.

Check out the Best Pharmaceutical ERP Software for Business.

Streamlining Batch Production and Inventory Management

When you automate certain aspects of pharma business like batch records, recipe management, and inventory tracking with process ERP software, work becomes faster and more accurate. This software lets teams create batch files, update formulas, and track raw materials and finished goods with minimal mistakes, and reduces paperwork and errors, improving both control and compliance.

And this way, for pharmaceutical manufacturers, serialization and expiry checks are easy to handle, where every item can be traced with a special number and expiry date. This helps avoid stockouts and stops expired products from being shipped. With these controls, companies can follow all industry rules and avoid costly penalties.

Managing Supply Chain and Procurement for Reliable Operations

To efficiently manage and improve the supply chain here, businesses can use an erp system pharmaceutical industry designed for the pharma sector’s complex needs. This ERP helps manage procurement by keeping track of many vendors and scheduling timely deliveries. It also links logistics and warehouse operations to keep products moving smoothly without delays.

In these systems, real-time inventory control is another key feature, where the system tracks stock levels immediately and sends alerts if supplies run low or products near expiry. It also supports vendor tracking and demand forecasting by analyzing past sales and market trends, which then lets pharmaceutical manufacturers avoid shortages or excess stock, ensuring medicines are available when needed and following compliance rules.

Check out some Pharma ERP Challenges Opportunities Tips.

Managing Quality Control, Data Integrity, and Risk Management

As we know that pharma products have to maintain the highest and potent quality of their products, it is important for companies to take quality control seriously. With pharma ERP software, every batch and process step can be checked and recorded with quality checks, deviation management, and corrective actions. The system helps log any mistakes or issues, letting teams fix problems quickly and keep high product standards.

So in this industry, ensuring strong data integrity is also required in pharma production. A modern ERP system pharmaceutical industry supports safe storage and quick access for all quality records, where internal audits are made easy with traceable audit trails and proper electronic signatures, making it simple to prove compliance when needed.

For risk management, good ERP platforms can send automatic alerts for quality failures or process deviations, as here the teams can see all quality data on real-time dashboards, and compliance monitoring tools help make sure companies follow every required rule. These controls give pharmaceutical manufacturers confidence that their products are safe and always meet strict standards.

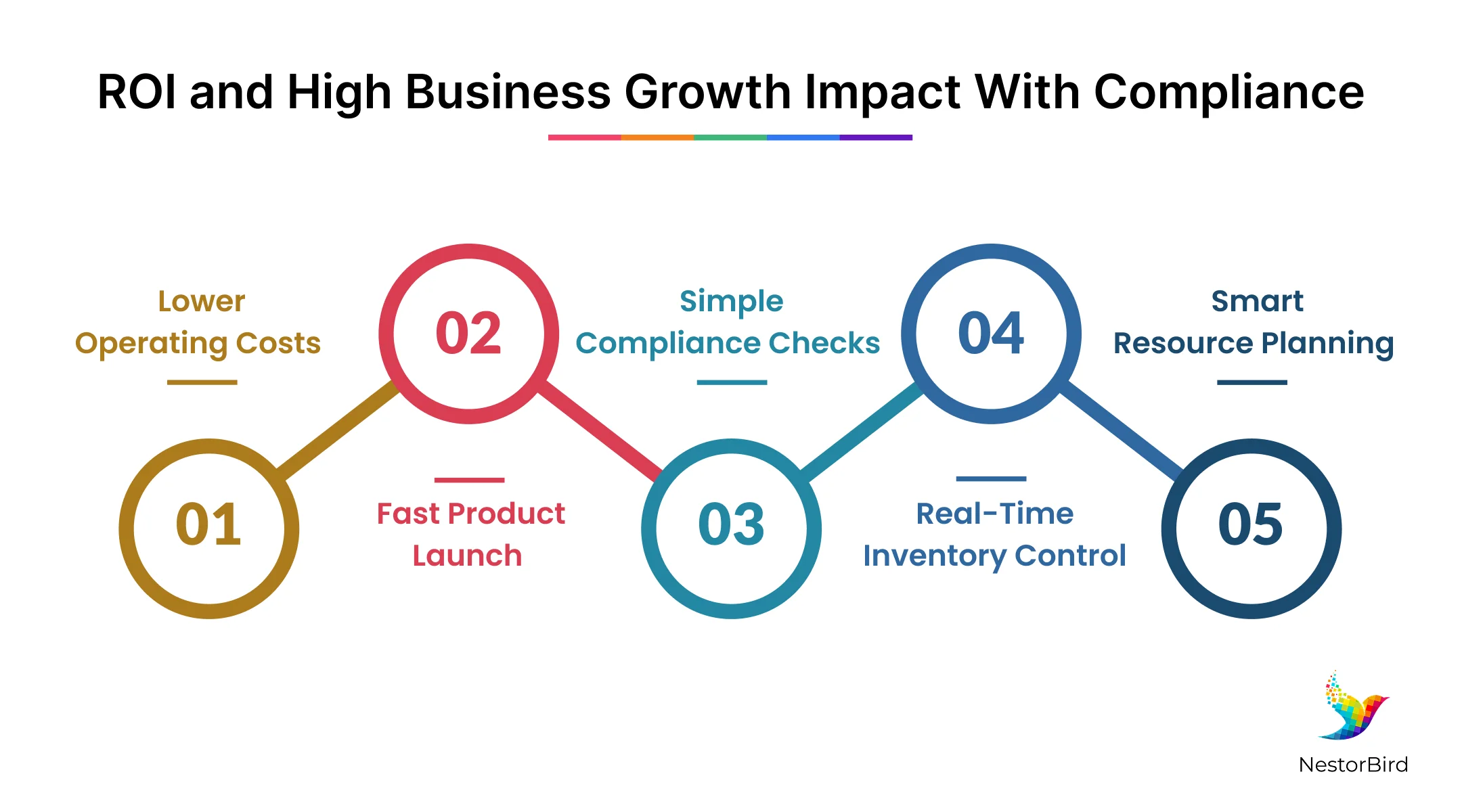

ROI and High Business Growth Impact With Compliance

Using pharma ERP software cuts down on daily running costs. It helps manage all resources better, like materials and staff time, so there is less waste and fewer mistakes. Every department becomes more efficient, making the company spend less to get the same work done.

With proper ERP tools, pharmaceutical manufacturers have fewer compliance problems. The software makes it easy to store, check, and share all documents needed for audits. This reduces the chance of missing any required records and helps avoid mistakes with regulations.

A good pharmaceutical ERP leads to faster product launches. All production steps happen in order, and records are automatic, so companies can quickly answer customer needs and release new medicines into the market without hold-ups.

Using an erp system pharmaceutical industry makes it simple to see where resources are needed most. The software can plan and move money, materials, and people where they are needed, leading to more balanced workloads and less waste across the company.

ERP also supports the sustainable growth of the pharmaceutical industry. It helps to plan better, find future market trends, and make smart business choices. Over time, this leads to more stable profits and allows the company to grow safely in a changing industry.

This is Why Data Integrity Is Key to Pharmaceutical Compliance.

Conclusion

Process ERP software is an important tool for the pharma industry. It helps companies follow strict rules, keep track of production, and control costs. It is best to choose ERP solutions from NestorBird because we offer easy-to-use, customized software for pharmaceutical manufacturers, that also helps keep companies compliant and ensures production runs smoothly, with reliable support whenever needed.

Frequently Asked Questions

Process ERP software is a digital system that helps pharma businesses manage production, inventory, compliance, and tracking, making all work steps simple, fast, and error-free.

ERP tracks every stock item, serial number, and expiry date. It sends alerts if products are soon to expire or stock runs low. This keeps medicines safe and always available.

ERP solutions can be integrated with CRM, LIMS, and other business tools. This helps pharma companies share data easily and improve operations across all departments.