Quick Summary

Batch processing in pharma means making products in groups called batches. It helps keep quality consistent and follows strict steps in the pharma manufacturing process. This blog explains the benefits, challenges, and software used in batch manufacturing.

Table Of Contents

Introduction

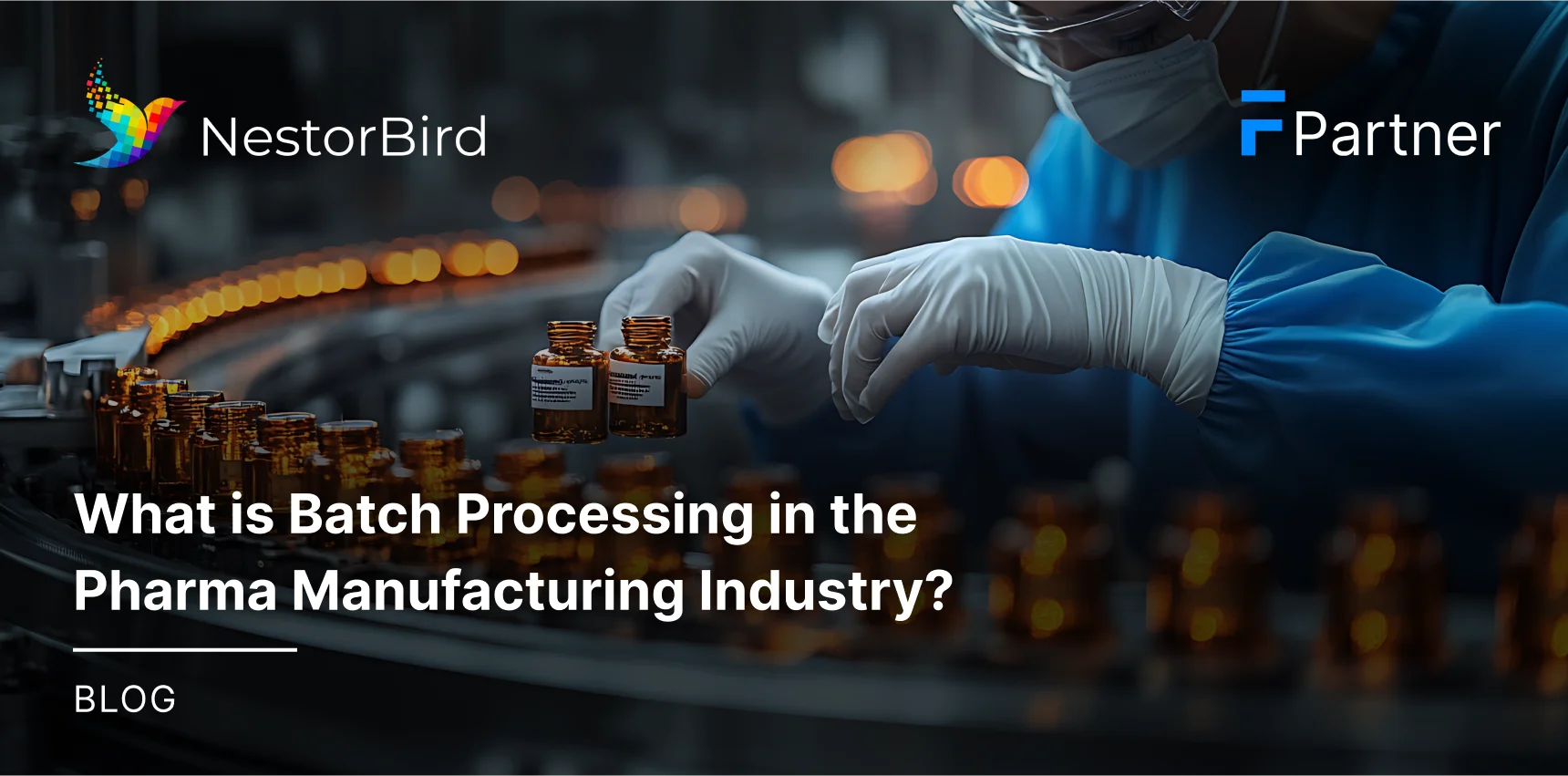

In the pharmaceutical industry, its potent and useful products are usually made using batch processing. This method involves producing medicines in specific groups called batches. Each batch follows a set process to ensure the medicine is safe and consistent. Batch processing is important because it helps maintain quality and control throughout the manufacturing steps. In this blog post, the focus will be on explaining what is batch processing in pharma and its key role in the production of medicines.

Key Takeaways

Batch processing helps keep medicine quality consistent in pharma manufacturing.

It allows making products in set groups, making it easier to check quality.

Pharma ERP software helps manage batch records and inventory efficiently.

Batch processing can quickly isolate and recall problem batches if needed.

Detailed record-keeping in batch manufacturing improves regulatory compliance and traceability.

Understanding Batch Processing in Pharma Manufacturing

During the manufacturing process of the pharma products, it is important to understand batch processing in manufacturing. Batch processing means making a fixed quantity of a medicine or product in one go before starting the next batch. This helps keep quality consistent and makes sure each batch follows the same steps to meet required standards.

The batch manufacturing process involves making the product step-by-step in batches. Each batch moves through stages like mixing, processing, and packaging. Only after finishing one batch can the next one start. This allows companies to control quality at every step.

Also, pharma processing can use either batch processing or continuous manufacturing. The key difference is that batch processing makes products in groups, stopping between batches, whereas continuous manufacturing runs production without stopping. But here, batch processing is preferred when detailed quality checks are needed.

Here, the types of batches include:

Pilot Batch: This is usually a small batch made to test and improve the pharma manufacturing process. It helps check the production steps and quality before making larger batches, and is mainly used for development and testing.

Production Batch: This batch is the regular large batch made for sale, which follows all the detailed steps and quality checks after the process is fully tested. It meets the standards required for customers and stores.

This is How ERP Enhances Efficiency Compliance Pharma.

The Main Steps in the Pharma Batch Manufacturing Process

Here are the main steps that manufacturing companies need to follow in the batch manufacturing process, explained simply:

Planning and Raw Material Preparation: This step involves gathering and checking all needed raw materials. Proper planning ensures all ingredients are ready and meet quality standards before production starts. This is key in any pharma manufacturing process for smooth workflow.

Weighing, Dispensing, and Blending: Materials are carefully weighed and measured to match exact formulas. After weighing, ingredients are mixed or blended to make a uniform batch. Accuracy is important for consistent product quality in batch processing in manufacturing.

Processing Steps like Granulation, Compression, Coating: The batch goes through detailed steps like granulating powders, compressing into tablets, or coating tablets for protection. Each stage must follow strict procedures to ensure final product quality and safety during pharma processing.

Check out the Top ERP Software Solutions.

Quality Control during Pharma Manufacturing Process Stages: At every stage, quality checks happen to confirm the product meets safety and effectiveness standards. Testing and inspections keep the process controlled and compliant with regulations in the pharma manufacturing process.

Packaging, Labeling, and Batch Release: Finished products are packed securely and labeled with needed information like batch number and expiry date. This step prepares the batch for distribution, ensuring traceability and compliance in pharmaceutical batching.

Importance of Pharmaceutical Batching Records and Traceability: Detailed records called Batch Manufacturing Records (BMRs) and Master Batch Records (MBRs) document the entire process. These records help trace each batch’s history, ensuring accountability and quality control in batch manufacturing.

What Are The Benefits of Batch Processing in Pharma Manufacturing

There are many benefits for pharma manufacturing businesses when they use batch processing:

Batch manufacturing process helps improve quality control by testing each batch separately. This reduces errors and keeps products safe. It also helps keep rules in check during production.

This way of processing also offers flexibility to produce different quantities as needed. Companies can quickly adjust production to meet changes in market demand without wasting materials.

The process makes it easier to find defects in a specific batch. If there is a problem, only that batch is recalled, saving costs and protecting customers from faulty products.

Using pharma ERP software and pharma manufacturing software automates tasks in batch production. It helps monitor the whole process and reduces mistakes by tracking every step precisely.

Batch processing improves documentation and reporting for regulatory compliance. It keeps detailed records, making inspections easier and helping manufacturers stay within legal standards.

Get more info on the Inventory Management Software in Pharma Manufacturing.

Challenges You Can Face in Batch Processing in Pharma Manufacturing

Let us understand what are some of the challenges that companies can face during the batch processing of pharma products.

Regulatory compliance is a major challenge, and here the pharma companies must follow strict rules that vary by country, making it hard to meet all requirements in the batch manufacturing process, which also slows down production and adds costs.

Human errors can often happen when switching between batches, and these mistakes can affect product quality and safety. So, careful management is needed to reduce errors in pharma processing.

Inventory and production downtime occur between batches, so the machines must be cleaned and reset before starting the next batch. This causes delays and lowers overall efficiency.

Managing raw materials and keeping batch consistency is difficult, because the differences in materials or process changes can cause quality variations, so maintaining uniformity is essential in the pharma manufacturing process.

The Role of Pharma Manufacturing Software & ERP in Batch Processing

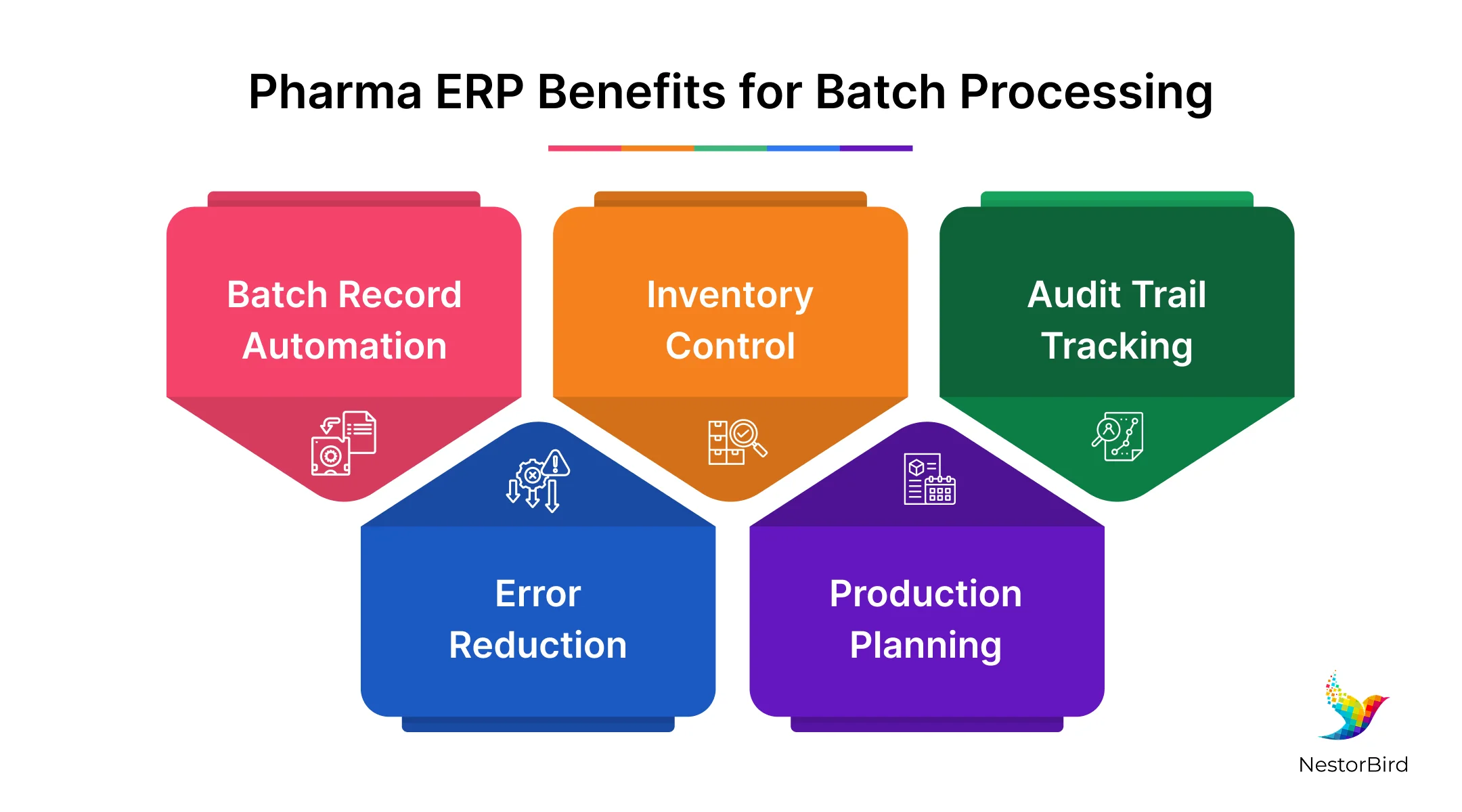

When pharma manufacturing companies use efficient pharma ERP software, it helps simplify and speed up the entire pharma manufacturing process. This software connects different departments, making the workflow a much smoother process.

Pharma manufacturing software automates batch record keeping and controls inventory, and effectively creates audit trails, helping track every step clearly. This reduces manual errors in batch processing.

Know more about the pharma supply chain software.

Pharmaceutical production industry software makes it easier to keep detailed batch documentation. It supports compliance by ensuring all records meet regulatory standards without much manual effort. Plus, these software tools also improve production planning, as they help manage resources and schedules better, reducing delays and mistakes in the manufacturing process.

Conclusion

Batch processing is very important in pharma manufacturing. It helps companies produce quality medicines safely and follow the right steps at each stage. Using the right system can improve how well batches are managed and tracked. You should consider using ERP solutions from NestorBird, as the software is made specifically for the pharmaceutical industry and helps keep your production compliant, organized, and efficient. With real-time data and easy integration, NestorBird supports pharma businesses to grow safely and stay competitive.

Frequently Asked Questions

Batch manufacturing keeps product quality consistent. It allows testing of each batch separately, making sure medicines are safe and meet regulations.

Pharma ERP software automates batch tracking and inventory, reducing errors and helping companies stay organized and compliant.

Quality checks happen at every stage of production. They ensure the product meets safety, purity, and effectiveness standards before release.